In the nascent days of the cannabis industry, pioneers relied on sheer determination and manual processes to serve patients in need. Amidst legal uncertainties, early efforts were strictly hands-on, from trimming buds to managing patient records with pen and paper. Yet, as the industry matures, the tide is turning toward innovation and efficiency, propelling businesses into a new era of automation and artificial intelligence (AI).

Inspired by traditional industries including agriculture, pharmaceuticals, and consumer packaged goods, operators have adopted technologies that streamline operations from plant cultivation to packaging and logistics. The shift is not just about saving time and cutting costs. Automation, particularly when combined with AI, also helps refine product quality to meet operator and consumer expectations.

Over the past several years, as the industry has matured and become exponentially more competitive, operators have leaned into automation in a big way, especially in the cultivation and manufacturing verticals. Two of the most active areas for research and development are robotics and artificial intelligence (AI).

Robotics

The term “robot” arose from the old Church Slavonic word robota, meaning “servitude,” “forced labor,” or “drudgery.” Although we often think of robots as humanoid automatons straight out of science-fiction movies, at their most basic robots comprise any automated machines or processes that free humans from tedious or repetitive tasks. And they needn’t exist in physical form. Software programs that automatically interact with social media are referred to using the casual abbreviation “bots.” Text-based virtual customer-assistance agents have been dubbed “chatbots.” Systems that compile and analyze data or operate environmental controls also could be called bots, as could the software “brains” that help vehicles operate safely, track maintenance needs, and diagnose problems. By offloading common, repetitive tasks like those onto automated systems, humans conserve time and energy, reduce stress and boredom, and can focus brain power and memory on other mission-critical tasks.

“Your team can do a lot more than sitting in a circle and rolling the same thing 500 times a day,” said Tomer Oliel, director of operations for automated irrigation solutions provider RootsTalk. “I don’t see many negatives to increased automation. You free up time and labor, which means you can start taking on things that are a little more meaningful for your company’s development.”

More importantly, automation can make the difference between profit and loss in rapidly growing industries with slim margins. Automation speeds up production, decreases the potential for errors and injuries, increases consistency, and reduces labor costs.

“It’s difficult for operators without automation to compete,” said Sorting Robotics’ founder and Chief Executive Officer Nohtal Partansky. “The difference can be as significant as fighting guns with bows and arrows: It’s a slaughter.”

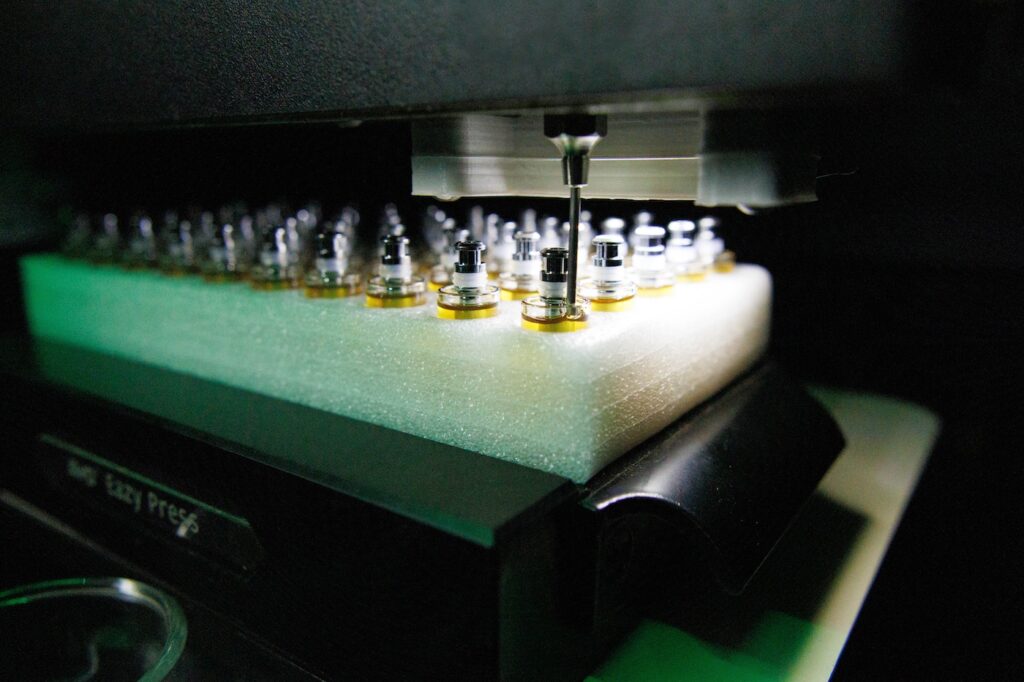

Partanksy and his team developed one of the industry’s first manufacturing robots designed for a specialized use: producing coated pre-rolls. With the assistance of a single operator, the Stardust robot can produce up to 960 kief-coated joints per hour. The machine doesn’t expose the raw materials or the operator to contamination, and the finished products are uniform, unlike their hand-dipped counterparts.

Combined with an automated pre-roll production system like Hefestus’s AuraX, which can produce up to 2,000 Dutch-crowned pre-rolls per hour while reducing staffing needs by as many as sixteen people, the potential for per-unit cost reduction is sizable, even incorporating the initial cost of the equipment.

The pre-roll sector is particularly ripe for automation. Now the third most popular product category in the United States behind flower and vapes, pre-rolls accounted for nearly 20 percent of total 2023 U.S. sales and a whopping one-third of sales in Canada. Pre-roll production traditionally has been labor-intensive, requiring meticulous handiwork to ensure consistency in weight, density, and shape, but machines have revolutionized the segment. In addition to Hefestus, companies like Futurola have developed advanced rolling solutions that increase not only productivity but also consistency and product quality. Futurola’s Knockbox 3/300 system, for example, can fill and pack 300 pre-rolls in two minutes, with a variance in weight between joints of less than 0.02 grams.

“A pre-roll has to be consistent every time, and humans are not that,” Oliel said. “We are all different; we bring different feels and touches to our work. With automation, you can increase productivity, consistency, and your overall customer experience.”

Of course, increased manufacturing output capabilities require corresponding increases in raw materials. Automation, and particularly robotics, plays a pivotal role there, as well. Cultivation has become a veritable hotbed of innovation, pushed constantly forward by not only economic but also ecological imperatives. Automated systems now control lighting, irrigation, and climate, optimizing plant growth conditions and maximizing yield while minimizing resource waste.

Neatleaf’s Spyder, an semi-autonomous robotic platform, caused quite a stir upon its debut late last year. Mounted at four points above the canopy, the platform’s cable-based multisensor drone-like inspector functions like a football stadium’s “eye in the sky,” constantly roaming and capturing millions of data points as it monitors every plant in an indoor grow, regardless of the room’s size.

According to Neatleaf founder and CEO Elmar Mair, crop loss can reduce a grow’s output by as much as 20 percent, and a substantial amount of crop is lost due to pests or diseases not spotted and addressed quickly enough by human laborers—no matter how painstakingly they examine their leafy charges. Because of the degree of attention to detail required, manual examination takes time, and time can be an enemy in environments requiring moment-to-moment precision. Consequently, the industry loses billions to crop damage every year, Mair said.

Neatleaf’s robot addresses all of that. Aided by AI, the system provides real-time, actionable insights about everything from carbon dioxide concentration and relative humidity to leaf and air temperature. Heatmaps can identify microclimates and systemic issues in a room, helping growers recognize issues quickly and address them before trouble spreads.

The goal, Mair indicated, is to provide human oversight, but better, stronger, and faster. “The measure of ‘quality’ is based on humans,” he said. “Humans try to understand what’s going on in the grow space; our system relies on that understanding to detect root causes and figure out solutions. Not a lot of experts are able to do that, and if they’re already swamped with repetitive tasks just to keep things moving along, the industry suffers from a major bottleneck.

“Being able to detect and understand viruses, bacteria, and diseases early on so you can address [a problem] before it spreads—that will change the crop loss landscape significantly,” he added.

Artificial intelligence

Like every other industry on the planet, cannabis is leaning into artificial intelligence to drive efficiencies and unlock new earning potential. AI and automation make particularly potent partners.

“Inventory and manufacturing are where AI makes a significant difference,” said Marcus Tillson, chief operating officer for end-to-end extraction solutions provider Root Sciences. “It’s great at taking larger datasets and figuring things out from there to benefit your company.

“Taking a step back from cannabis, just look at the mainstream technological breakthroughs we’ve seen since the pre-Industrial Age,” he continued. “Each one gets faster and more complex, and those developments are so much more impactful for us today. Joe Average didn’t have to struggle too hard to understand inventions of the past. A horse and cart were easy to figure out, but a car? Not so much. The more we progress as a society, the less likely Joe is to intuitively understand emerging technologies.”

That’s where AI can be hugely beneficial. Suddenly Joe has an easily accessible, biddable digital companion who can help him make sense of what once was arcane. Even the simplest machines constantly generate data: revolutions per minute, time to complete a task, error rate, et cetera. Harnessing and analyzing that data in real time can provide operators with insight that might take humans days, weeks, or months to reach on their own. AI reduces friction, allowing automation to produce even greater efficiency. With greater efficiency comes the ability to scale and produce more revenue at a lower cost per item.

“The way any industry should approach automation and AI-enabled efficiency tools is to start looking for the lowest-hanging fruit—that is, the easiest process to automate,” said Ryan Hoitt, founder and CEO of cart-filling machine manufacturer Vape-Jet. “Then move on to the next piece, and keep evaluating as you go.

“AI is going to keep bringing enormous efficiencies to business operations,” he added.

Hoitt cited an example: The Vape-Jet team developed an AI-assisted bot for their office Slack channel. The bot allows users to sign in and request complete breakdowns of technical support issues, including the entire history of an issue, a summary of progress that’s been made toward a resolution, and previous customer-support requests featuring similar issues with commentary about similarities and differences and how those issues were resolved. This all happens instantly, within seconds of the moment a team member clicks “help” on the interface. Then, the bot generates suggested troubleshooting steps and links to resource documentation. The system helps Vape-Jet’s team assist clients quickly and with much less friction than humans could achieve on their own.

“Thanks to AI, I’ve been able to keep my team really lean. Because we prefer to focus on company progress rather than menial tasks, I make sure we’re forward-leading when it comes to implementing these sorts of tools,” Hoitt said. “From an office admin perspective, we accomplish as much as teams ten times our size accomplish.”

Because of the complexity of the processes, AI is only in its use-case infancy in extract production. But with its ability to analyze massive amounts of data almost instantaneously, the technology could prove transformative for extraction labs and consumers.

“As this technology improves, we can get even more particular about what we’re going to extract from the plants,” said Marc Beginin, founder and CEO of Prodigy Processing Solutions, which designs and builds automated extraction systems. “The whole process of putting together a consumable good, especially if it’s used to treat a particular ailment, will become much less strain-dependent. All you have to do is look at the strain’s compounds and think about what your patients need, and you can pull from a variety of plants.”

Beginin is a big-picture kind of guy. He envisions AI’s impact on his sector starting well before biomass meets machine. “[AI] can reduce the cost of the grow and, in turn, lower the cost for the end consumer,” he said. “As a result, weed becomes more accessible. Health and livelihood are no longer based on the availability of a particular strain. AI can analyze the effectiveness of different cannabis extracts, and new strains will be designed for specific therapeutic purposes.”

Labor issues

Automation and AI present almost limitless potential for businesses, but workers are somewhat less enthusiastic. As machines assume tasks previously performed by humans, an underlying fear of reduced employment opportunities grows. Workers worry “smart machines” will replace them.

The concern is not unreasonable. A study performed by MIT economists Daron Acemoglu and Pascual Restrepo found about 400,000 workers were displaced by factory automation in the U.S. between 1990 and 2007, at a rate of about 3.3 workers per robot. According to Time magazine, as many as 42 percent of the 40 million American jobs lost during the height of the COVID-19 pandemic were replaced by automation.

But technology has been displacing human workers for efficiency’s sake since the dawn of the Industrial Age. A mechanical device called the Spinning Jenny replaced the laborious process of hand-spinning yarn in the 1770s, revolutionizing textile production. James Watt’s modifications to steam-engine technology led to the rise of factories and the introduction of mass-produced goods—a situation Henry Ford further refined by introducing assembly-line processes. During the twenty-first century, as part of what some have dubbed the Internet Age, automated toll booths replaced human attendants on turnpikes nationwide. Kiosks displaced some fast-food servers, and the internet killed most travel agencies. In cannabis, mechanized flower-trimming supplanted some hand-trimmers despite the delicate nature of the job.

Workers adapted by learning new skills. After all, no matter how sophisticated some automated technologies are, machines are not yet capable of truly autonomous behavior—even when they’re partnered with AI.

“I don’t think jobs will be totally displaced,” said Prodigy’s Beginin. “Humans are harder to break than robots. You’ll always need oversight to make sure your machine is doing its job.”

Because humans still must oversee, program, and maintain automated equipment, forward-thinking companies are investing in training programs that equip their workforces with the skills necessary to operate and manage new technologies. The approach not only mitigates the impact of job displacement but also opens new career opportunities within the industry.

Human nature has pushed technological development and deployment forward since the invention of the wheel. As Vape-Jet’s Hoitt observed, change is inevitable.

“From an ethical standpoint, I believe the best way forward is societal change fueled by AI and automation,” he said. “Rather than wallow in this in-between period, let AI come for our jobs. It’s going to happen eventually anyway. Whether we make that a long, drawn-out process or barrel our way through it and force the change to happen, our collective goal has to be whatever provides the best human outcome to us on the other side. I strongly believe that automation not only propels our industry forward but also sets the stage for a more profitable future.”

And there will always be a market for small-batch, handmade goods. Masters of their craft—cultivators, trimmers, edibles chefs, extractors, and others—can’t compete with large operations on price or volume, but craft goods find an enthusiastic reception among connoisseurs.

What’s next?

As Root Sciences’ Tillson mentioned, technology becomes more complex and advancements occur more quickly over time, thanks to the way each new innovation takes advantage of previous developments. With AI now assisting on every level from ideation to execution, research-and-development cycles may reach warp speed. But that doesn’t mean adoption will keep pace.

“It’ll probably take another three to five years for us to see some really awesome stuff in automation advancements, but there’s a need across the chain, especially for the craft guys,” said Bryan Gerber, CEO of pre-rolled cone manufacturer Hara Supply. “They need highly specialized equipment, while the Curaleafs of the world are just looking for highly efficient machinery so they can pump out numbers.” Multistate operators, whose business model relies on efficiency across the board, often have the financial resources to adopt new technologies early in their life cycle. Keeping an eye on the processes and equipment they favor can provide clues about what technologies will have staying power, he added.

As for the categories most likely to be impacted by emerging automation trends, especially those incorporating AI, Gerber’s bet is on niche products in the consumer goods space. “I think people are looking for that experience and are willing to pay more for it,” he said, thereby making innovation in the sector more feasible.

The beverages sector is primed to benefit, as well, according to Iron Heart Canning Vice President of Sales Roger Kissling. Iron Heart operates an automation-heavy mobile canning plant that packages beverages at the source, freeing manufacturers from the expense of running in-house operations. “I believe the beverage category has immense potential when it comes to analyzing automated datasets,” he said. “It’s well-positioned to satisfy a particular type of consumer other products in the industry aren’t geared toward. If we can use technology to tailor beverages to be a bit more ‘functional’—in other words, mood-boosting, anxiety-reducing, or stress-relieving—it will open cannabis up to a much broader audience.”

Even more potential awaits in the research lab, where the plant and its compounds still represent a vast, unexplored frontier. “Last year at the Emerald Science Conference, I met a group that had developed a synthetic cannabinoid to quantitatively shrink the size of tumor cells in a rat,” Partansky said. “That was the first time I’ve seen something scientifically tested, and it was done by trial and error to develop a novel cannabinoid not found in the plant. Now, imagine using a robotic fleet powered by AI brute-forcing thousands of experiments a month. Think about how much we could change. What might the world look like when we use the power of AI to unlock the secrets of the endocannabinoid system once and for all? It’s a future I’m excited to be a part of, and so should everyone else in the industry.”

A role for augmented reality?

You’ve used them to immerse yourself in games like Beat Saber and Resident Evil, but could augmented reality (AR) headsets have a place in the cannabis industry? A team at Wageningen University & Research in the Netherlands, led by robotics and automation researcher Joseph Peller, PhD, is wrapping up four years of research into how AR might be used to augment cultivation practices. Their findings indicate products like Apple’s new Vision Pro could help cultivators estimate yield simply by scanning the tops of plants.

And that’s just the tip of the proverbial iceberg, according to thought leaders embedded in the industry day in and day out.

“Imagine this,” said Prodigy’s Beginin. “You could be in California and put on a pair of glasses that allow you to walk through a grow in Massachusetts. You can move your hands and watch a robot touch a plant for you 3,000 miles away. Our director of innovation is based in Alaska. If we can [virtually] stand in that freezing-cold lab with the operator and tell them what they’re doing wrong without having to leave our homes? That’s phenomenal.”

Vape-Jet’s Hoitt envisions a role for AR paired with robotics, automation, and AI. In his futuristic vision, the combined technologies not only free their human collaborators from physical unpleasantries but also have agency.

“Imagine a bot that can go through your cultivation space and say, ‘Oh, that cola is perfect. I’m picking it today.’ It sounds great, but I don’t believe that’s the best application for AR because of its limitations,” he said. “Now, if you combine AR with robotics and automation and use that for crop input, the idea might be more beneficial. That way, you’ll have better imaging sensors, [the grow worker] won’t get tired, your vision system won’t get sweaty, and you won’t ever find yourself having to walk through humid environments with a bunch of electronics strapped to your head.”

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://mgmagazine.com/business/manufacturing/the-case-for-automation/