Sign up for daily news updates from CleanTechnica on email. Or follow us on Google News!

How much technological and economic idiocy can be jammed into a single week and why does it have to rhyme? Quite a lot it turns out and no idea.

Two different clearly nonsensical purported climate solution technologies received far too much fawning press in the past few days. The first is Heirloom Carbon, yet another direct air capture technology of the type that the fossil fuel industry and venture capitalists love. The second is AirLoom Energy, yet another firm that doesn’t understand the physics and economics of wind energy, and didn’t bother to search for prior art before building something inane. Both are funded by Bill Gates, of course.

Heirloom Carbon

Let’s start with Heirloom. Actually, let’s start with the connotations of the word heirloom. As branding goes, it’s amusing. After all, an heirloom, whether a sideboard or a fruit tree, is something from the past, cherished for its historical roots much more than its current obsolescence.

And technical obsolescence is what Heirloom is leaning into. They are trying to reverse entropy with a Rube Goldberg mechanical device in an age of low-carbon electricity and computers. They are artisanal carbon dioxide removers, hipsters of carbon drawdown, extracting homeopathic amounts of the greenhouse gas with authenticity and a technology stack that could have been built in 1900.

Hipsters and Silicon Valley startups are both games for trust fund kids, so this is intersectional privileged affluence of no importance except perhaps as a spotlight on our current culture.

So what is Heirloom Carbon doing? Well, they are a direct air capture (DAC) technology startup. As I noted recently, the definition of DAC is:

A tax-break scam that has ensnared venture capitalists at the behest of keeping fossil fuel companies in business.

I’ve looked at most DAC technologies, some of them in great depth, like the fossil fuel industry fig leaf that is Carbon Engineering, recently sold to Occidental Petroleum, its only customer. As I noted when I was assessing the technology and firm in early 2019, its only natural market was enhanced oil recovery on tapped out oil fields with unmarketable volumes of natural gas to power it’s kilometers of 20 meter high fans and the 900° Celsius heat required to separate the CO2 back out of the chemical substance that captured it.

Heirloom is in a similar vein, attempting to accelerate mineralization, a process where atmospheric CO2 bonds with a handful of types of rocks to create things like carbonates. I assessed the accelerated weathering of magnesite with the use of catalysts in 2018, and have looked at but not published extensively on the olivine weathering, perhaps the best known in the field. I’ve spoken with the founders of Global Thermostat and the CEO of a European direct air capture initiative as well.

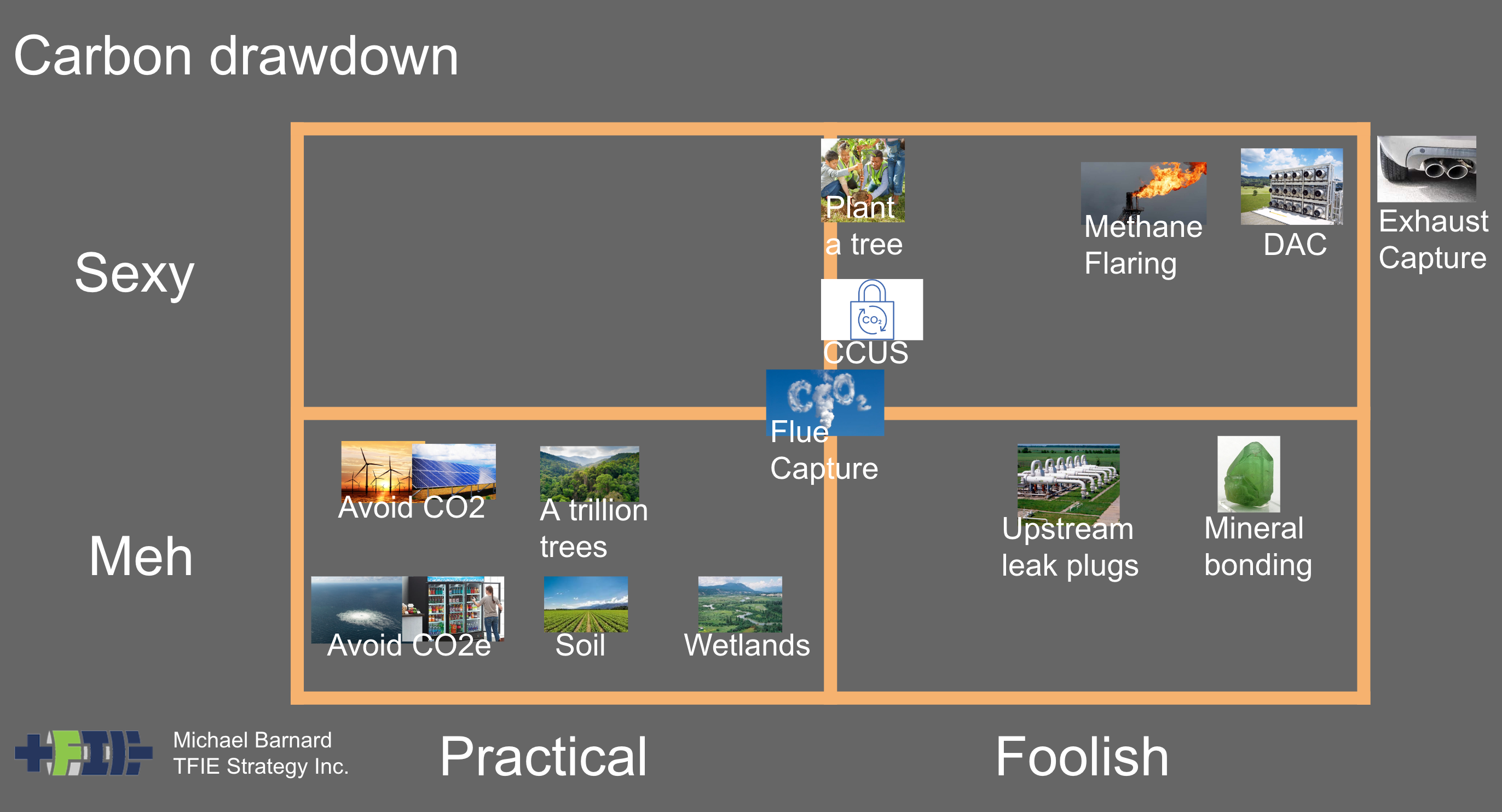

I’ve spent enough time and effort on the space that DAC is in the sexy and foolish quadrant of my atmospheric carbon assessment.

Why is it sexy? Because everyone wants a silver bullet and no one wants to change. When discussing direct air capture with Dr. Joe Romm, now working with Michael Mann at the new Penn Center for Science, Sustainability, and the Media, the other day, the analogy I made was to sand on a beach.

The amount of CO2 in the atmosphere is 420 parts per million. Removing it is like being sent to a beach with a million grains of black sand with the task of finding and removing the 420 grains of dark gray sand that were mixed in with it while someone else is adding grains of gray sand in random locations on the beach all the time. Venture capitalists love direct air capture despite the Sisyphean inanity of the idea.

What are mineralization’s drawbacks? Well, speed and surface area mostly, which are interrelated. While the minerals that absorb CO2 are somewhat porous, it takes a long time for CO2 to seep in and bond. And portions of the mineral remain inaccessible, so no CO2 bonds to it.

Every mineralization scheme inevitably runs into this problem, and tries to find hacks that don’t mean that they have to crush minerals into dust with mechanical energy and keep mining minerals.

Heirloom has reached the nadir of this pathway. They’ve reinvented the limestone kiln used in cement manufacturing and instead of making useful low-carbon cement, they’ve turned it into a complex ouroboros, the snake that swallows its own tail.

Yes, they put some crushed limestone in a kiln, heat it up with electricity and create quicklime, just like a cement kiln. When limestone is heated, a bunch of the carbon in it bonds with oxygen from the atmosphere to make fairly pure carbon dioxide. This is captured and then there’s an expectation that it will be sequestered underground somewhere, and they claim that they are going to sell it to a low-carbon cement firm instead of just fixing limestone kilns.

How crushed? Like well under 0.5 millimeters crushed, the previous gold standard which was still too slow, which is to say dust. Then they take the quicklime and spread it on big trays and mix it with water. Then they slide the trays into very slow moving vertical conveyor gizmos. The trays are exposed to air for 2.5 days and some atmospheric CO2 attaches to the quicklime to create fine limestone again. Their claims aren’t independently validated, but they are claiming much better performance than other solutions, at the expense of rather absurd mechanical complexity and more energy of course.

Then they put the newly created limestone back in the kiln and start the process again.

They have to keep this all inside a very well ventilated building of course, one where drafts are carefully controlled. After all, the very fine sand they are creating will blow around very easily but they still need to add grains of CO2 sand to the air in the building from the outside. I suspect regardless of how carefully they try to manage this it will get in everything and foul and degrade their mechanical components much more rapidly than they assume. I doubt they’ll reach a thousand tons a year, and I doubt their equipment will operate for more than a handful of years without very significant and expensive maintenance.

What’s the net CO2 drawdown of this? Well, they are starting as noted at homeopathic concentrations of drawdown but like all darlings of VCs are talking about billions of tons, none of which will ever materialize.

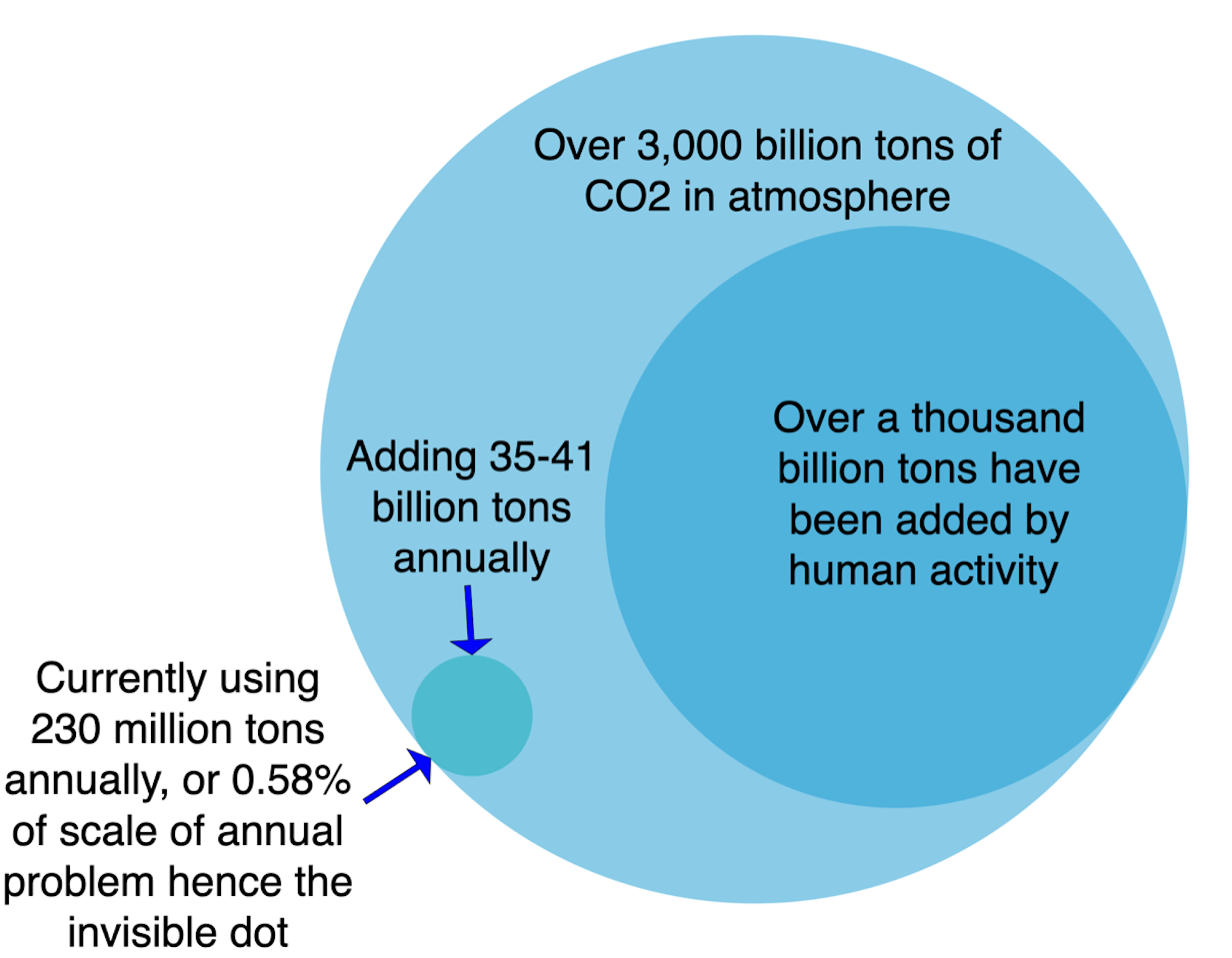

This is a diagram I created years ago to illustrate the scale of the problem. Heirloom’s 1,000 tons per year are a pimple on the invisible dot of the total global market for CO2 today.

That total global market of 230 million tons does have about 90 million tons which are put underground today, but of course that’s for enhanced oil recovery, the only real market for carbon ‘sequestration’ outside of farming tax payer money. As I noted recently in my lengthy piece on supercritical CO2, the only high volume user of that interesting state of matter is for enhanced oil recovery.

Like Carbon Engineering, the only natural market for this nonsensical Rube Goldberg contraption is in the Permian Basin where enhanced oil recovery and carbon capture subsidies will be the order of the day. And the end result will be more CO2 from the oil that’s recovered.

Why things like this get fawning press is due to three different challenges. The first is the STEM illiteracy of most people. The second is the deep desire on the part of a lot of people to be allowed to keep making a massive mess and have a maid service that cheaply cleans up behind them. The third is, of course, the VC’s promoting this stuff massively in an attempt to get their money out before it inevitably crashes.

AirLoom Energy

Every year new nonsensical wind generation devices are announced. Every year credulous journalists leap on them as if they are amazing and will be better than the boring masts with three blades that are an incredible, effective, efficient and reliable source of electricity globally.

Every year, the previous year’s crop disappears and is never heard from again. One of this year’s crop is AirLoom Energy, which like many bad climate solutions is backed by Bill Gates. He’s behind Heliogen, the concentrating solar power innovation which ignores every reality of the industrial heat requirements it purports to solve. He’s behind Terrapower, the small nuclear reactor startup that he asked Congress for billions in subsidies for, receiving another $80 million recently. He read far too much Vaclav Smil, when that otherwise useful big picture analyst made fundamental mistakes related to energy because he was too far from it, and as a result has discounted the reality of wind, solar, transmission and electricity storage for well over a decade.

AirLoom makes the same mistakes that are repeated over and over and over in wind generation. In fact, they make the same mistakes in virtually exactly the same way as a failed wind generation innovator from the early 1980s, Transpower. Failure to pay attention to prior art is one of my red flags of technological innovation. Pro-tip to investors: if a Google search of under a minute finds something that looks a lot like what is being pitched from a decade or more ago and you’ve never heard of it, it’s likely a bad investment.

Sheerwind Invelox was an example of this in wind generation. It was one of a decades long string of attempts to concentrate air flow on a much smaller wind turbine that crashed and burned economically every time since the first attempt in the 1930s.

What is it that AirLoom and Transpower are doing? Well, instead of putting the wind generator up where the air is stronger, they are keeping it closer to the ground because that’s cheaper. Except that the wind is stronger and less turbulent further from the ground, and energy in the wind is a function of the cube of the wind velocity. Small increases in wind velocity increase energy return tremendously, and AirLoom says, “The heck with that!”

This is similar also to John Dabiri’s schools of counter-rotating vertical axis wind turbine fish which I first assessed over a decade ago now, including a lengthy back and forth with the MacArthur Genius Grant winner. It doesn’t matter how cheap and simple a wind generator is, unless it’s in stronger winds, it’s just not going to make much electricity. At least Dabiri found and attempted to exploit a new effect, but AirLoom has nothing going for it.

They put a bunch of blades on a track that’s a few meters off of the ground and formed into an oval. The blades are attached around their center of gravity. The blades catch the wind and move around the track in concert with the other blades, in principle. Then small generators in the posts holding up the tracks the blades are mounted to extract electricity from the movement of a cable inside the track.

All they’ve done is take a vertical axis wind turbine and put the axis on the outside, solving exactly none of the problems with that perpetually failing form of electrical generation. It’s like hubless wheels on motorcycles, in that it looks cool to people incompetent at mechanical engineering, but doesn’t provide any actual benefits.

And AirLoom isn’t simple at all. What’s a wind turbine? It’s a base with concrete and rebar. It’s a mast, a big cylindrical tower of steel that just sits there. It’s a nacelle, the big box with the horizontal axis and generator. And it’s three blades. The blades rotate. The nacelle can yaw into the wind with electric motors. The blades can pitch with electric motors for more efficient grabbing of the wind. That’s it.

The blades are always in the best winds because the mast is tall and the blades are long. Most of the energy comes from the top third of the diameter of the blades, above the nacelle itself, because wind speed increases with the power law of wind, which is a mild exponential function of height. AirLoom’s Rube Goldberg device operates below the level of the lowest points wind turbine blades reach.

Could wind turbines have blades that flew through the air at the low levels that AirLoom is designed for? Sure, but no one bothers because the energy in the air there isn’t worth harvesting.

Wind turbines don’t bother to start operating until the wind is 10 to 15 kilometers per hour because the energy in air that slow is much, much lower. They reach peak performance around 50 kilometers per hour of steady wind.

And that steadiness is something else AirLoom foregoes. Laminar turbulence increases as you get closer to the ground, which tends to be lumpy and cause eddies. AirLoom’s right in the most turbulent portion of the wind, and turbulence sucks energy out of wind generation systems.

Finally, wind turbine blades always operate in clean air ahead of the mast. They are getting the smoothest possible wind at the highest possible velocities, which is why they having been getting taller, not shorter, for decades. The blades are always strongly aligned to the direction the wind is coming from because the nacelle yaws into the wind.

AirLoom’s blades forego every single one of those advantages. The blades in the front of the device are close to the ground, so there’s more turbulence. They are behind the track and posts, so there’s more turbulence. They can’t pivot into the wind because the posts are fixed to the ground, so only a fraction of the blades in any device are well aligned to the wind. The blades on the downwind side of the loop are flying through dirty air from the blades in the front of the loop. And the friction from the cable running on the inside of the track will suck a bunch of the energy that remains.

AirLoom is such a terrible idea that no one should have reported on it except in dismay that such a bad idea even made it into a tiny prototype. But Gates put $4 million into it, so all of a sudden it’s a press darling.

I was unsurprised to find that the ‘inventor’ of this device had two things in common with failed wind energy innovators I’ve looked at in the past. The first was that he has no background in energy, electricity generation or wind energy, and has no STEM background. He’s an MBA who worked in finance.

One of my business model red flags questions is: Do the principals in the firm have any related qualifications? in this case, zero, nada, zip, bupkiss. Apparently Gates and co think that’s unnecessary.

And the principal is also a kite surfer, a sport I’ve enjoyed which is the source of countless failed wind generation technologies. I like kite surfers on the water and love playing with parafoils, including paragliding the southern cliffs of Bali a few times, but there’s something about a lot of kite surfers that make them think that recreation turns into generation without passing the slightest of sanity checks or knowing anything about electrical generation or the grid.

So there you have it. Both Heirloom and AirLoom are variants of long-failing technological pathways. They are both massively mechanically complicated for little return. They are both funded by Bill Gates. They are both destined for the dust heap of history. It’s remarkable that anyone would give them money, and it’s remarkable how much fawning press they’ve received. In this case, history is both repeating itself, and rhyming.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

EV Obsession Daily!

[embedded content]

I don’t like paywalls. You don’t like paywalls. Who likes paywalls? Here at CleanTechnica, we implemented a limited paywall for a while, but it always felt wrong — and it was always tough to decide what we should put behind there. In theory, your most exclusive and best content goes behind a paywall. But then fewer people read it!! So, we’ve decided to completely nix paywalls here at CleanTechnica. But…

Thank you!

Iontra: “Thinking Outside the Battery”

Advertisement

CleanTechnica uses affiliate links. See our policy here.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://cleantechnica.com/2023/11/13/heirloom-airloom-prove-that-cleantech-stupidity-often-repeats-even-occasionally-rhymes/