Complex and Complexity

When discussing Supply Chains and their Flows (of items, money, data and information), the terms Complex and Complexity (or complicated) are commonly used. While sounding similar, they are different.

The Supply Chains Network of a business is an example of a system that is complex. The Network contains many organisations with varying relationships that can be dependent, independent and interdependent, which can modify as circumstances change. Also, a major event such as the entry or exit from the Network of a significant customer or supplier can change outcomes. But these outcomes ’emerge’ from the system and are difficult to predict, as the parties can behave differently, depending on many influences from within the Network or the external environment. A complex system cannot be managed; instead the effort must be put into understanding the system.

Complexity relates to the internal systems and processes of a business, such as those used by the Supply Chains group (Procurement, Operations Planning and Logistics). Processes that are complicated or have complexity may have evolved over time, or have been directed by management. The design of processes within the ‘core’ supply chains (between the organisation and its Tier 1 customers and suppliers) is also influenced by:

- Breadth: the number of Tier 1 suppliers in the supply base

- Depth: the number of Tiers of suppliers in each supply chain

- Geography: the global spread (therefore distance) from the organisation’s facilities to its customers and suppliers

- Focus within the organisation’s operations: whether on speed and efficiency, rather than effectiveness through the business

- Safety margins in the business: which can be low concerning time, inventory and working capital

- External events: such as new regulations enacted by governments or merger and acquisition (M&A) activity

Because each element in a complicated internal process is known and reacts the same way each time it is accessed, the many elements of the ‘core’ supply chains planning and scheduling processes can be simplified and restructured. However, the outcomes will become part of a complex system that is your organisation’s Supply Chains Network.

Reducing Complexity

Planning supply chains has different types and degrees of complexity depending on the industry and particular business. But from analysing the data available and identifying patterns about customers, suppliers, production and deliveries, an indication of complexity can be obtained. The recommended actions noted below may not all be applicable for your business or are too difficult for senior management to accept.

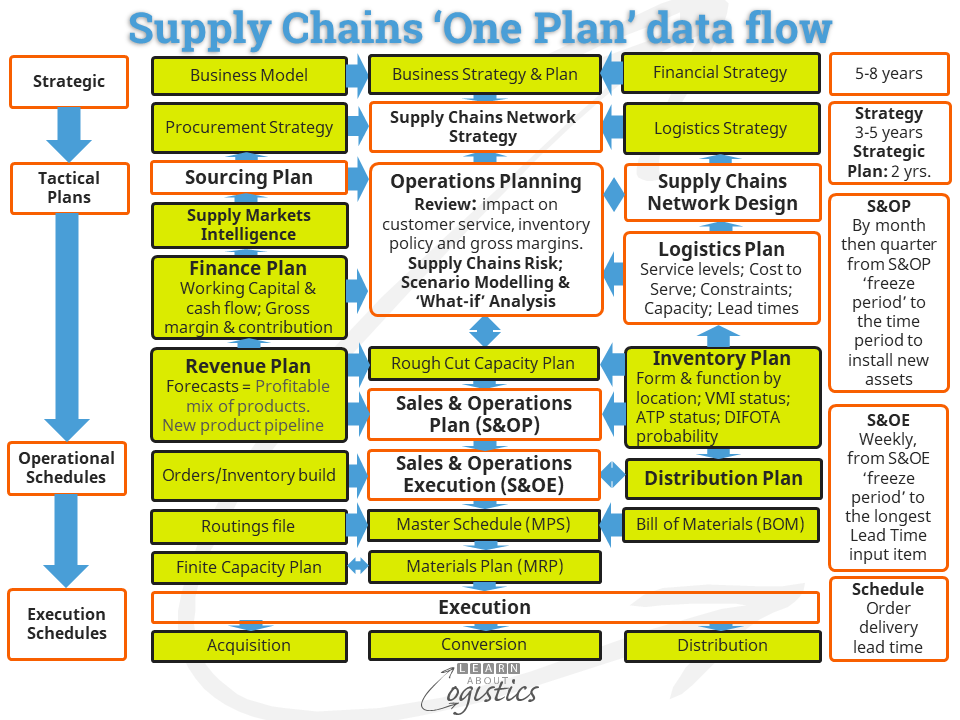

- Identify and agree about the form in which the planning takes place. It should be based on ‘one version of the truth’ for all parts of the organisation to use the ‘One Plan’. The Sales & Operations Plan (S&OP) process, identified in the diagram, is the ‘heart’ of the ‘one plan’. The objective of S&OP is to balance demand and supply and identify and plan for potential trends and disruptions over an agreed horizon.

2. Implementing the S&OP process helps to change thinking about the organisation structure from individual functions to groups and flows. Participants in the S&OP process are:

- ‘Sales’ group for the demand side of an enterprise. It includes: Sales, Marketing, Product Development and Demand Planning

- ‘Operations’ group to supply products and services for sale. It includes the Supply Chains group (Procurement, Operations Planning (and scheduling) and Logistics); Manufacturing/Production and Technical/Engineering

- Finance evaluates the proposed plans for effect on working capital, cash flow and profitability

- IT and HR/Personnel provide inputs concerning the availability of resources over the S&OP horizon

3. The information store for the Supply Chains group is the Supply Chain Network Design Map. This identifies and describes the characteristics of Nodes and Links in the Network and how they interact, which can help to identify risks, inefficiencies and opportunities for improvement. In addition, it must also identify the formal and informal relationships (including where the exercise of power and dependency occur) between the Tier 1 customers and suppliers of the various organisations. Because it is dynamic, the Map is always a ‘work in progress’, that must be continually updated by the Supply Chains group for use as an input to the Sales & Operations Planning (S&OP) process.

The Supply Chains Network Design Map can enable discussions about the preferred locations for suppliers and whether a move to regional and local inbound supply chains is justified by a reduction in complexity.

4. Segmentation recognises that not all business relationships are created equal. For better planning and improved results, the task is to segment the finished products or stock keeping units (SKUs), purchased items, suppliers and customers into groups for differentiated planning.

5. A simplification action that will be contested by Sales is to rationalise the number of SKUs that have been launched as line extensions, to form the ‘long tail’ of products. These can provide inefficiencies in scheduling and inventory control. A typical outcome is that the number of SKUs discontinued will be added by other products to ‘meet market demand’ and the cycle is then repeated.

6. If a consumer products company requires a long tail of low selling product lines, it must invest in quick change-over production and packing equipment and multiple small ‘work in process’ holding vessels. This type of investment allows a business to adapt its business model so that production time is within the delivery lead time of the customer. That is to move from ‘make to stock’ to ‘make to order’, which eliminates the need to forecast specific product configurations.

7. Another approach is to design products such that their production can be delayed at stages through the process. This is Postponement, which saves adding costs to a product until there is an order.

8. A similar approach to product design is the consolidation of inbound material items and packaging to enable better contracts by Procurement. Of many examples is 47 different size screws and fasteners in an electronics assembly business and 13 types of pepper in a food manufacturer.

Through all the activities to reduce complexity in planning the business, the Supply Chains group must emphasis collaboration through the S&OP process and improved communications with customers and suppliers. These also simplify the planning process.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://www.learnaboutlogistics.com/reducing-complexity-for-planning-your-supply-chains/#utm_source=rss&utm_medium=rss&utm_campaign=reducing-complexity-for-planning-your-supply-chains