Introduction

Today’s highly competitive industrial environment necessitates a continuous focus on increasing production uptime and decreasing downtime. Manufacturers are working on predictive maintenance by leveraging IoT Edge technology, a ground-breaking gadget, to boost industrial efficiency and productivity. In this article, we will explore the specific ways that innovative companies are utilizing IoT Edge to outperform their competitors and not just stay afloat.

What is IoT?

Investments in digital transformation are becoming more and more important for companies, but many of them find it difficult to grow because they haven’t given enough thought to identifying the business objectives that these investments should be supporting. Although there are many distinct forms that digital transformation can take, Internet of Things (IoT) technology is a common underlying technology.

The Internet of Things drives digital transformation across the majority of Industry 4.0 operations that rely on data delivery from linked devices and sensors to connected people, goods, and processes. IoT solutions enable manufacturers to connect, monitor, analyze, and act on real-time data. This unique technology reduces costs throughout the production process, boosts revenue growth, and enhances efficiency.

The Impact of IoT on the Manufacturing Industry

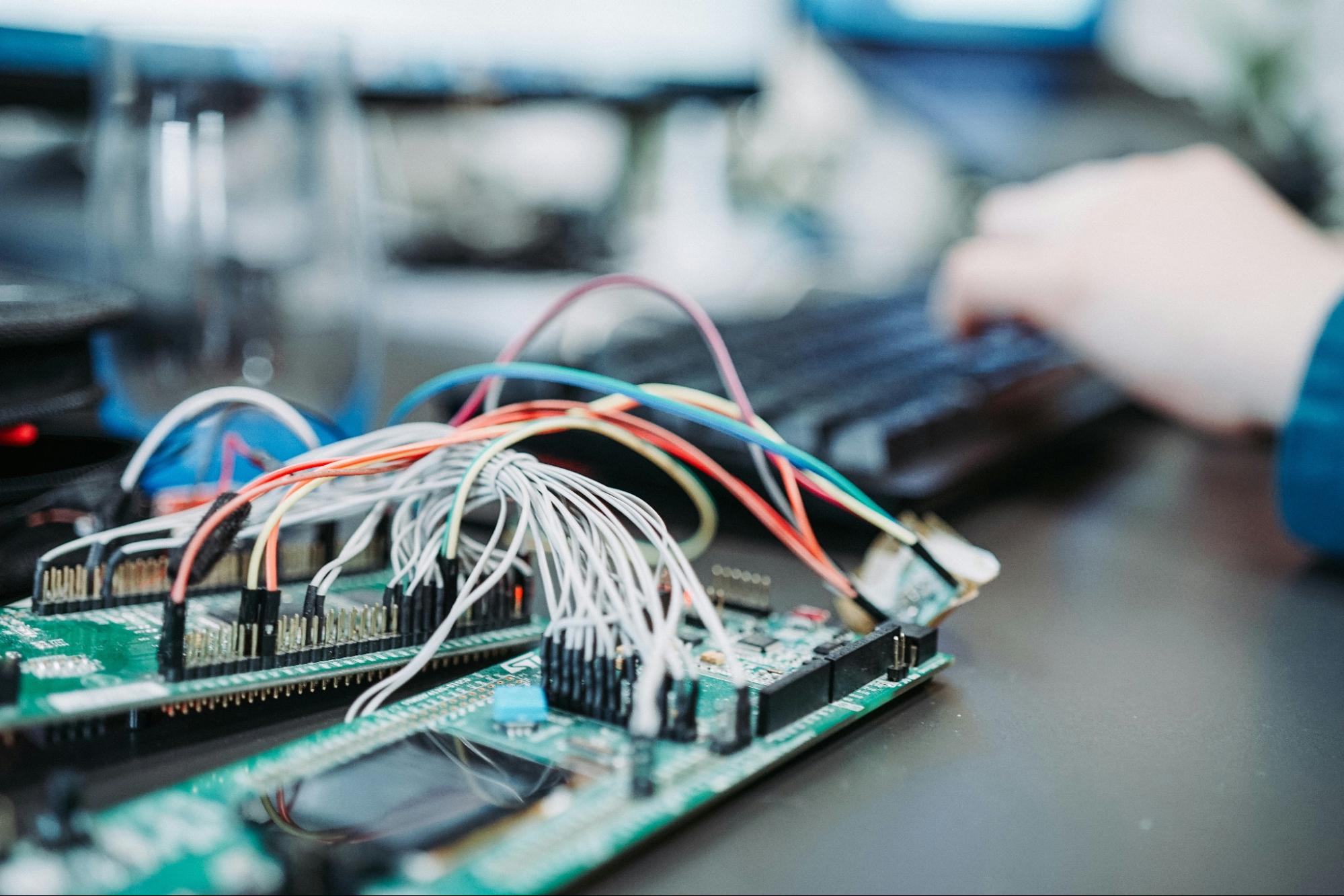

Robots for industrial use are common on the production floor due to their accuracy, precision, durability, and speed. Manufacturers can boost the effect of industrial robots by connecting them to IoT devices. Integrated Manufacturing IoT sensors enable machines to share data, coordinate operations, and interact with one another. IoT devices boost robotic productivity and efficiency by allowing robots to share data, while also improving safety and reducing the need for unexpected maintenance.

Use Cases of IoT-Based Predictive Maintenance

Despite what most people believe, IoT predictive maintenance isn’t limited to manufacturing facilities. Other sectors also profit from this breakthrough technology, although it is particularly promising for the manufacturing industry. So, let’s examine the top five IoT-based predictive maintenance use cases:

Transportation & Logistics

The Internet of Things transforms global logistics and redefines transportation systems. And we are here to prove it. IoT sensors installed on trucks, containers, ships, and vehicles track cargo status, temperature, humidity, and position in real time. Predictive maintenance, in this situation, enables firms to optimize routes, reduce freight damage, and shorten deliveries.

Healthcare

IoT-based predictive maintenance is transforming patient care and medical equipment management. IoT sensors are used in hospitals to monitor essential medical equipment such as MRI machines and ventilators. It promotes patient safety and minimizes costly downtime.

Manufacturing Equipment

Other applications of the Internet of Things predictive maintenance include the manufacturing industry. Companies utilize IoT sensors to monitor the condition of their machinery and equipment, detecting anomalies in vibration, temperature, and other key metrics. The predictive maintenance technology, in turn, warns maintenance staff of potential faults before they cause breakdowns. This streamlines manufacturing operations and minimizes downtime.

Benefits of IoT in Manufacturing

There are various benefits of IoT in manufacturing. Automated manufacturing systems are intended to handle complex operations with minimum human interaction. These systems improve each stage of the production process by utilizing cutting-edge technology such as robots and artificial intelligence (AI).

Improved Safety

Automation increases workplace safety by reducing the number of accidents and injuries caused by human labor and hazardous operations. Automated devices follow tight security standards and regulations. They also minimize the possibility of any human error, while also maintaining guidelines with the industry requirements for processes.

Improved Operational Efficiency

By using IoT solutions, manufacturers can automate additional operations, detect abnormalities, and decrease errors, thereby increasing operational efficiency. IoT can enable industrial robots to operate autonomously by leveraging sensors, cameras, wireless devices, and edge computing to execute tasks such as assembly, finding defects, organizing, stacking, and routing.

Quality Improvement and Defect Reduction

Digital transformation processes have the potential to greatly increase quality. Robotic systems combine cameras, sensors, artificial intelligence, and machine learning to monitor product quality quicker and more precisely than humans, discover problems, and respond rapidly.

Challenges of Using IoT for Predictive Maintenance and Quality Control

IoT projections for the future indicate that it has the potential to revolutionize predictive maintenance and quality control in the manufacturing industry; nevertheless, a number of IoT security problems must be addressed before its use.

Insufficient Skill Set

The advanced systems of Industry 4.0 sometimes need a particular skill set, which one may lack in the workforce. Recruiting, educating, and retraining people in user interface design, data science, software development, and machine-level controls can be difficult.

Data and IT Security

The growing connectivity in Industry 4.0 has sparked concerns about IT security. Cyber assaults, network misconfigurations, and device failures are all examples of dangers that can interrupt operations when processes and systems are integrated online.

New Business Models

Digital technologies can generate new business models, requiring companies to work on their strategies. Aligning internal perspectives on these strategies can be challenging, especially in driving the transformation.

Conclusion

In conclusion, the use of IoT in manufacturing has transformed the sector by allowing manufacturers to optimize production processes, foresee maintenance difficulties, and check product quality in real time. As technology advances, the advantages of industrial IoT in production are only expected to grow. As a result, companies must embrace disruptive technologies in order to compete in the marketplace. They also can fully grasp the promise of IoT by collaborating with an IoT app development company or a mobile app developer to offer tailored solutions to their specific demands and aims.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- BlockOffsets. Modernizing Environmental Offset Ownership. Access Here.

- Source: Plato Data Intelligence.