Sublime Systems, a startup pioneering a revolutionary method of producing fossil-fuel-free cement, has been chosen by the U.S. Department of Energy’s Office of Clean Energy Demonstrations (OCED) to start negotiations for up to $87 million in funding under the Bipartisan Infrastructure Law and Inflation Reduction Act.

The funding, part of the Industrial Demonstrations Program, aims to support projects like Sublime’s First Commercial Electrochemical Cement Manufacturing initiative. Selected among 33 projects spanning over 20 states, these initiatives collectively receive up to $6 billion to showcase their commercial-scale decarbonization solutions.

These efforts are crucial for transitioning energy-intensive industries towards net zero emissions. They can also help bolster local economies, generate high-quality jobs, and mitigate harmful emissions detrimental to public health.

Cement’s Carbon Challenge

To understand the innovative strides of Sublime Systems, it’s crucial to grasp the conventional cement-making process and its environmental hurdles.

Cement, when mixed with water, sand, and gravel, constitutes concrete, the second most consumed substance globally after water. This process has remained largely unaltered for centuries.

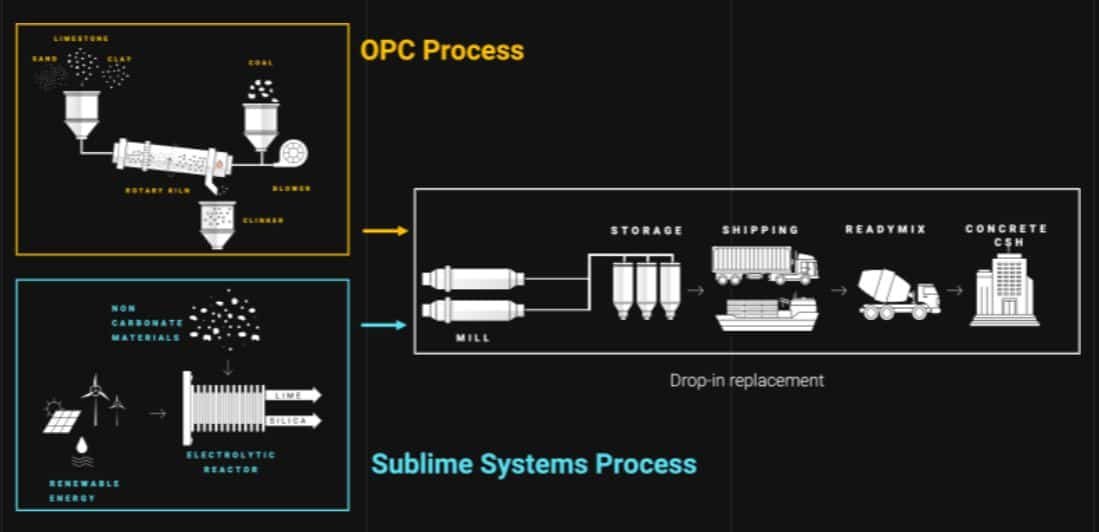

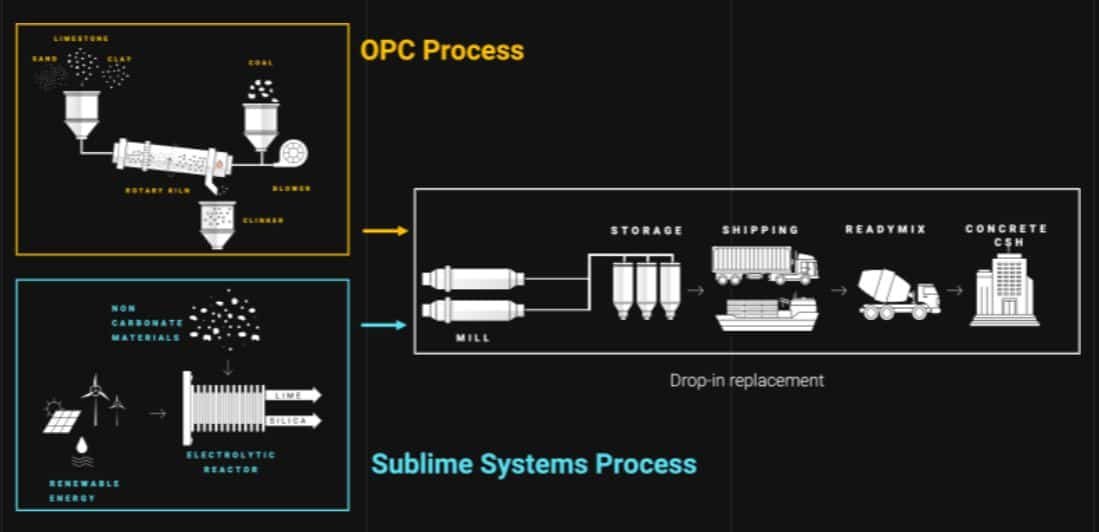

Unfortunately, producing traditional cement contributes significantly to carbon emissions, accounting for about 8% of the world’s total emissions. That’s because using ordinary Portland cement (OPC) process to manufacture traditional cement relies on fossil-fueled kilns operating at extreme temperatures.

This is what Sublime Systems will try to address. Founded in 2020, the Massachusetts-based company works with a clear mission – to revolutionize cement production and mitigate its environmental impact. Here’s the Sublime process of cement manufacturing:

Through innovative electrochemical processes, Sublime has scaled up its cement manufacturing to a pilot capacity of 250 metric tons per year (TPY). The forthcoming commercial facility in Holyoke will be capable of producing up to 30,000 TPY of Sublime Cement™. It’s slated to open as early as 2026, boasting significant reductions in fossil fuel pollution typically associated with industrial growth.

Sublime Systems’ approach hinges on two primary innovations: electrochemical reactions and renewable energy integration.

Instead of traditional methods that rely on high temperatures, Sublime employs electrochemical reactions to produce cement. This revolutionary approach eliminates the need for burning fossil fuels, thereby significantly reducing carbon emissions.

Then by using electricity to power these reactions, Sublime’s plants have the potential to integrate renewable energy sources such as solar and wind. This strategic shift reduces emissions and aligns with renewable energy goals, contributing to a more sustainable future.

Other companies are creating innovative ways to capture carbon dioxide to make it as an ingredient in its cement-free, carbon-negative concrete.

Sublime Systems’ Path to Sustainable Cement Production

Dr. Leah Ellis, CEO and Co-Founder of Sublime Systems highlighted the biggest hurdle hindering this kind of breakthrough innovation in fighting climate change, saying:

“Access to sufficient capital for industrial-scale demonstrations is the single biggest obstacle preventing breakthrough innovations from reaching the scale humanity needs to combat the climate crisis.”

Ellis praised the Department of Energy for addressing this obstacle through funding from OCED’s Industrial Demonstrations Program (IDP). She expressed excitement about collaborating with the department on funding their first commercial manufacturing scale-up. It would be able to produce clean cement while fostering economic opportunities for the surrounding community.

Furthermore, OCED applicants, including Sublime Systems, were mandated by the DOE to submit Community Benefits Plans (CBPs). These plans outline strategies to engage communities, create high-quality jobs, and prioritize economic and environmental justice for disadvantaged groups.

In Sublime’s case, their decision to establish their first commercial manufacturing facility in Holyoke, Massachusetts was guided by screening tools developed by Justice 40. The startup anticipates the creation of hundreds of jobs during the construction phase of the project.

The company has forged a strategic partnership agreement with the United Steelworkers (USW), representing approximately half of unionized cement workers in the U.S., focusing on operational roles in the Holyoke plant. Additionally, Sublime has entered into a Memoranda of Understanding to negotiate project labor agreements with building trade unions in the region for the construction phase.

Sublime Systems’ Holistic Approach

Augmenting Sublime’s Community Benefits Plan is a collaboration with the Smithsonian Science Education Center (SSEC). The OCED selection includes funding to leverage SSEC’s educational programming resources to support this objective.

U.S. Secretary of Energy Jennifer M. Granholm emphasized the critical role of advancing decarbonization technologies in pivotal industries such as steel, paper, concrete, and glass. She underscored the significance of President Biden’s industrial strategy, facilitating the Department of Energy’s (DOE) historic investment in industrial decarbonization.

Granholm highlighted the aim to substantially reduce emissions from hard-to-decarbonize sectors, ensuring that American businesses and workers remain competitive on the global stage.

Sublime has already secured reservations for over 45,000 tons of Sublime Cement™, demonstrating strong demand for their sustainable cement.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://carboncredits.com/sublime-systems-lands-87-million-funding-from-doe-for-low-carbon-cement/