| Jan 28, 2024 |

|

|

|

(Nanowerk Spotlight) Wearable sensors promise continuous, personalized health tracking beyond clinical visits. But most devices today still have fixed designs targeting single applications, lacking versatility to address users’ changing needs. Now, researchers report in Advanced Materials (“Hard Magnetic Graphene Nanocomposite for Multimodal, Reconfigurable Soft Electronics”) magnetically self-assembling graphene sensors that could enable the long-sought vision of modular, reconfigurable wearable electronics customized to individuals.

|

|

Balancing suitable electrical properties with biocompatible mechanical characteristics poses an enduring challenge for wearables development. Diagnostic accuracy and versatility improve with precise, adaptable sensors. Yet soft form factors that avoid irritating skin often conflict with adjustable, high-performance components requirements like hard magnets.

|

|

Prior reconfigurable wearable attempts sacrificed sensing capabilities or interconnection reliability compared to single-use devices due to these trade-offs. But the new study demonstrates magnetic graphene nanocomposites boosting sensor precision while enabling reliable self-assembly – combining the best aspects of both flexible biosensors and customizable electronics.

|

|

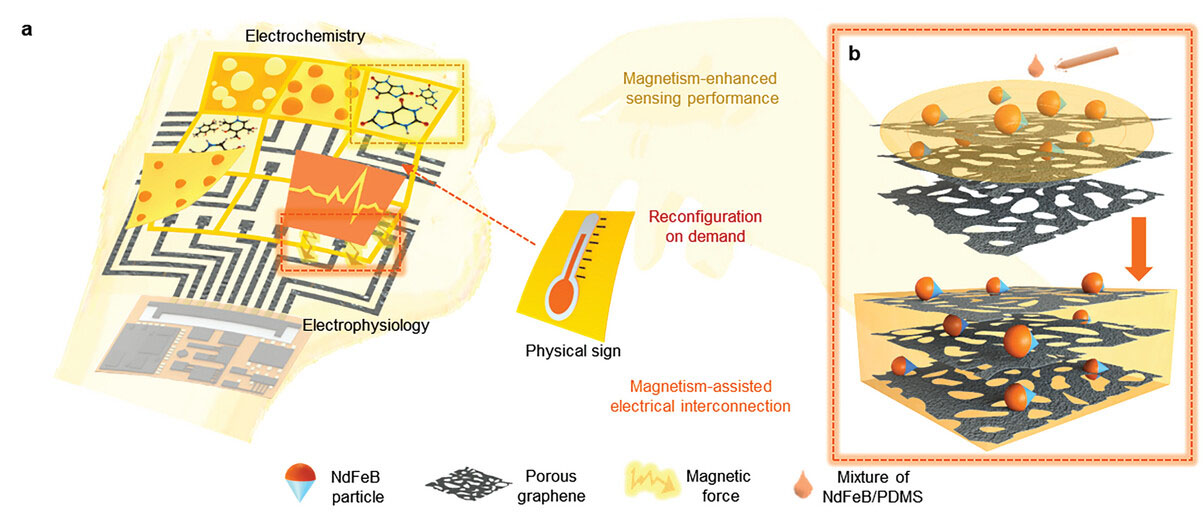

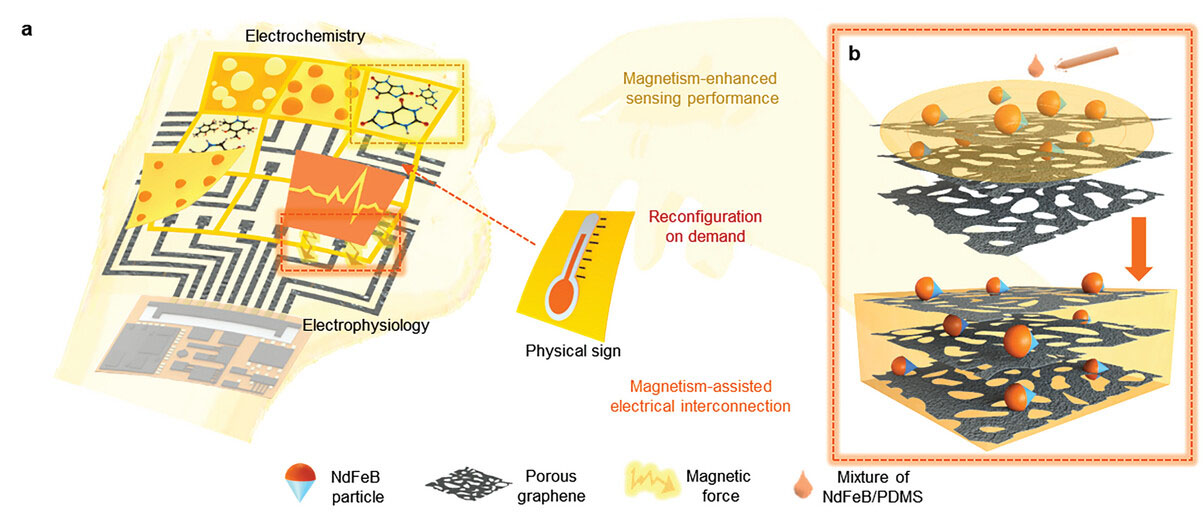

Recent materials advances have brought the dream device closer to reality. Graphene’s high conductivity and biocompatibility make it an intriguing base sensing material for skin-mounted electronics. By laser-inducing pores in a graphene film the researchers created a flexible, conductive network well-suited for diverse sensing modalities including electrochemical reactions, electrophysiology signals like ECG, and temperature changes.

|

|

The innovation lies in augmenting this sensing film with hard magnetic particles for self-assembly. The resulting “magnetic graphene nanocomposite” (HMGN) drives improvements in sensor performance while enabling reversible, reconfigurable connections.

|

|

| a) Schematic illustration of the reconfigurable soft electronics in magnetic graphene nanocomposite. b) Fabrication method of doping porous graphene with NdFeB. (Reprinted with permission from Wiley-VCH Verlag)

|

|

In their experiments, the researchers demonstrated that augmenting the porous graphene film with magnetic particles significantly boosts sensor capabilities. Tests showed the magnetic graphene nanocomposite improved sensor precision for metabolites like uric acid and pyridoxine by 70% and cut impedances for electrophysiological sensing by 87% compared to porous graphene alone.

|

|

For instance, uric acid sensors exhibited sensitivity increasing from 29.6 to 8 nA/µM-1 after magnetic doping. Meanwhile temperature sensors increased their sensitivity from 0.14 to 0.22% °C−1. The magnetically doped graphene also cut impedances for electrophysiological sensing by 87% – from 37.96 kΩ to 4.73 kΩ at 1 kHz frequencies.

|

|

Crucially, the magnetic domains allow HMGN films to snap together to form reliable electrical connections without solders or adhesives. Applied magnetic fields organize the haphazard magnetic domains into aligned north-south poles analogous to bar magnets. Opposite poles attract to self-assemble modular HMGN sensors on a flexible substrate into user-defined layouts.

|

|

The researchers tested this concept by fabricating an array of 16 impedance-sensing electrodes in HMGN. On command the square electrodes detached and re-assembled into circle and triangle shapes to map damaged tissue geometries. In other experiments swapping single HMGN sensors on a substrate adapted the device sensitivity, spatial coverage and sensing modalities like electrolyte concentrations, ECG signals and temperature.

|

|

The team integrated sensors for sodium, chloride and uric acid ions onto a platform to monitor sweat electrolyte loss during exercise. After collecting data the sensors detached so new ones for ECG and temperature could replace them to measure cardiovascular response, demonstrating HMGN’s potential for efficient multifunctional wearable electronics.

|

|

Such flexible, modular devices could advance personalized diagnostics and treatments tailored to individual patients and contexts. Continuous tracking of biophysical and biochemical markers outside clinical environments also promises to shift medicine toward preventative care instead of reactive approaches.

|

|

The path forward includes enhancing HMGN’s biocompatibility for more body locations and stretching sensor types to conditions like glucose, humidity and strain. While magnetically self-assembled electronics introduce promising reconfigurability, manual swapping still limits rapid device adaptations to multiple scenarios over short timespans. Fully integrated systems that rearrange modular plug-and-play sensors automatically in response to contextual inputs and usage patterns represent the next frontier.

|

|

Nonetheless, this breakthrough helps realize the vision of intelligent wearable devices that improve health by adapting to each user’s changing needs. Laser-induced magnetic graphene nanocomposites pave the way toward customizable multifunctional electronics that continuously monitor wellbeing around the clock across everyday activities. The modular, reversible approach developed here brings the dream of personalized, preventative and participatory medicine closer.

|

|

By

Michael

Berger

– Michael is author of three books by the Royal Society of Chemistry:

Nano-Society: Pushing the Boundaries of Technology,

Nanotechnology: The Future is Tiny, and

Nanoengineering: The Skills and Tools Making Technology Invisible

Copyright ©

Nanowerk LLC

|

|

|

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://www.nanowerk.com/spotlight/spotid=64522.php