Tools and strategies of systems metabolic engineering for the development of microbial cell factories for chemical production.

Chem. Soc. Rev. 2020; 49: 4615-4636

Is net zero carbon 2050 possible?.

Joule. 2020; 4: 2237-2240

Insights into the European Market of Bio-based Chemicals.

Publications Office of the European Union, 2019

US Biobased Products Market Potential and Projections through 2025.

Nova Science Publishers, 2010

Metabolic engineering of Escherichia coli for natural product biosynthesis.

Trends Biotechnol. 2020; 38: 745-765

Metabolic engineering strategies toward production of biofuels.

Curr. Opin. Chem. Biol. 2020; 59: 1-14

Systems metabolic engineering strategies: integrating systems and synthetic biology with metabolic engineering.

Trends Biotechnol. 2019; 37: 817-837

On the future fermentation.

Microb. Biotechnol. 2021; 14: 18-21

High cell-density culture of Escherichia coli.

Trends Biotechnol. 1996; 14: 98-105

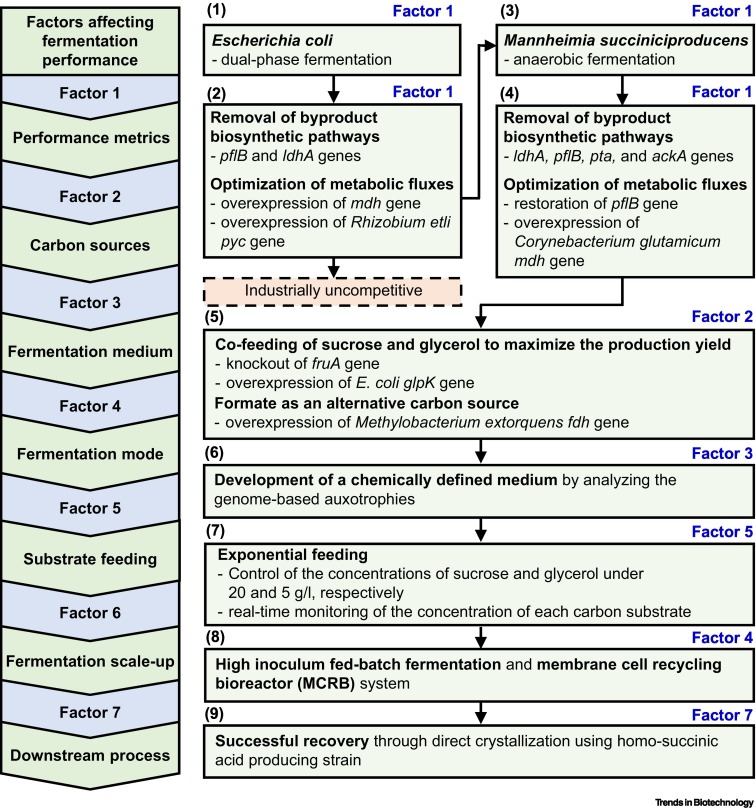

Enhanced succinic acid production by Mannheimia employing optimal malate dehydrogenase.

Nat. Commun. 2020; 11: 1970

Glutaric acid production by systems metabolic engineering of an l-lysine–overproducing Corynebacterium glutamicum.

Proc. Natl. Acad. Sci. U. S. A. 2020; 117: 30328-30334

Advances in bioconversion of glycerol to 1, 3-propanediol: prospects and challenges.

Process Biochem. 2018; 71: 134-146

Development of a commercial scale process for production of 1, 4-butanediol from sugar.

Curr. Opin. Biotechnol. 2016; 42: 118-125

Impact of synthetic biology and metabolic engineering on industrial production of fine chemicals.

Biotechnol. Adv. 2015; 33: 1395-1402

Synthetic biology’s first malaria drug meets market resistance.

Nature. 2016; 530: 389

Bio-vanillin: towards a sustainable industrial production.

Trends Food Sci. Technol. 2021; 109: 579-592

Microbial polyhydroxyalkanoates and nonnatural polyesters.

Adv. Mater. 2020; 32: 1907138

Systems metabolic engineering strategies for non-natural microbial polyester production.

Biotechnol. J. 2019; 14: 1800426

One-step fermentative production of poly (lactate-co-glycolate) from carbohydrates in Escherichia coli.

Nat. Biotechnol. 2016; 34: 435-440

Comparative efficiency and driving range of light-and heavy-duty vehicles powered with biomass energy stored in liquid fuels or batteries.

Proc. Natl. Acad. Sci. U. S. A. 2014; 111: 3360-3364

From the first drop to the first truckload: commercialization of microbial processes for renewable chemicals.

Curr. Opin. Biotechnol. 2013; 24: 1061-1068

Model-driven evaluation of the production potential for growth-coupled products of Escherichia coli.

Metab. Eng. 2010; 12: 173-186

A molecular switch that enhances productivity of bioprocesses for heterologous metabolite production.

Mol. Syst. Des. Eng. 2018; 3: 550-559

Dynamic strain scanning optimization: an efficient strain design strategy for balanced yield, titer, and productivity. DySScO strategy for strain design.

BMC Biotechnol. 2013; 13: 8

Novel two-stage processes for optimal chemical production in microbes.

Metab. Eng. 2020; 62: 186-197

The bioprocess TEA calculator: an online technoeconomic analysis tool to evaluate the commercial competitiveness of potential bioprocesses.

Metab. Eng. 2021; 65: 42-51

The emergence of adaptive laboratory evolution as an efficient tool for biological discovery and industrial biotechnology.

Metab. Eng. 2019; 56: 1-16

In situ recovery of fermentation products.

Trends Biotechnol. 1984; 2: 129-136

In situ recovery of bio-based carboxylic acids.

Green Chem. 2018; 20: 1791-1804

Systems strategies for developing industrial microbial strains.

Nat. Biotechnol. 2015; 33: 1061-1072

Evaluation of different biomass materials as feedstock for fermentable sugar production.

Appl. Biochem. Biotechnol. 2007; 137: 423-435

From lignin to nylon: cascaded chemical and biochemical conversion using metabolically engineered Pseudomonas putida.

Metab. Eng. 2018; 47: 279-293

Consolidated bioprocessing for bioethanol production by metabolically engineered Bacillus subtilis strains.

Sci. Rep. 2021; 11: 13731

Recent insights into consolidated bioprocessing for lignocellulosic biohydrogen production.

Int. J. Hydrog. Energy. 2019; 44: 14362-14379

Consolidated bioprocessing performance of a two-species microbial consortium for butanol production from lignocellulosic biomass.

Biotechnol. Bioeng. 2020; 117: 2985-2995

Consolidated bioprocessing performance of bacterial consortium EMSD5 on hemicellulose for isopropanol production.

Bioresour. Technol. 2019; 292121965

Consolidated bioprocessing of lignocellulose for production of glucaric acid by an artificial microbial consortium.

Biotechnol. Biofuels. 2021; 14: 110

Fermentation of glycerol and production of valuable chemical and biofuel molecules.

Biotechnol. Lett. 2013; 35: 831-842

Bioconversion technologies of crude glycerol to value added industrial products.

Biotechnol. Rep. 2016; 9: 9-14

Resource recovery and circular economy from organic solid waste using aerobic and anaerobic digestion technologies.

Bioresour. Technol. 2020; 301122778

Designing and engineering Methylorubrum extorquens AM1 for itaconic acid production.

Front. Microbiol. 2019; 10: 1027

Metabolic engineering of Methylobacterium extorquens AM1 for the production of butadiene precursor.

Microb. Cell Factories. 2018; 17: 194

Engineering Methylobacterium extorquens for de novo synthesis of the sesquiterpenoid α-humulene from methanol.

Metab. Eng. 2015; 32: 82-94

Microbial production of poly (hydroxybutyrate) from C 1 carbon sources.

Appl. Microbiol. Biotechnol. 2013; 97: 1407-1424

Synthetic formatotrophs for one-carbon biorefinery.

Adv. Sci. 2021; 8: 2100199

Escherichia coli is engineered to grow on CO2 and formic acid.

Nat. Microbiol. 2020; 5: 1459-1463

Renewable methanol and formate as microbial feedstocks.

Curr. Opin. Biotechnol. 2020; 62: 168-180

Metabolic engineering of Corynebacterium glutamicum for L-arginine production.

Nat. Commun. 2014; 5: 4618

Formic acid as a secondary substrate for succinic acid production by metabolically engineered Mannheimia succiniciproducens.

Biotechnol. Bioeng. 2017; 114: 2837-2847

Escherichia coli W as a new platform strain for the enhanced production of L-valine by systems metabolic engineering.

Biotechnol. Bioeng. 2011; 108: 1140-1147

High-yield production of L-valine in engineered Escherichia coli by a novel two-stage fermentation.

Metab. Eng. 2020; 62: 198-206

Increase of lycopene production by supplementing auxiliary carbon sources in metabolically engineered Escherichia coli.

Appl. Microbiol. Biotechnol. 2011; 90: 489-497

Enhanced 1, 3-propanediol production by supply of organic acids and repeated fed-batch culture.

J. Ind. Microbiol. Biotechnol. 2010; 37: 681-687

Efficient production of 1, 3-propanediol from crude glycerol by repeated fed-batch fermentation strategy of a lactate and 2, 3-butanediol deficient mutant of Klebsiella pneumoniae.

Microb. Cell Factories. 2018; 17: 92

Strategies for fermentation medium optimization: an in-depth review.

Front. Microbiol. 2017; 7: 2087

Large-scale production of enzymes for biotechnology uses.

Curr. Opin. Biotechnol. 2021; 69: 68-76

Plasmid addiction systems: perspectives and applications in biotechnology.

Microb. Biotechnol. 2010; 3: 634-657

Techniques for chromosomal integration and expression optimization in Escherichia coli.

Biotechnol. Bioeng. 2018; 115: 2467-2478

Effect of genomic integration location on heterologous protein expression and metabolic engineering in E. coli.

ACS Synth. Biol. 2017; 6: 710-720

Metabolic engineering of Escherichia coli for high-level astaxanthin production with high productivity.

Metab. Eng. 2018; 49: 105-115

Current status and applications of adaptive laboratory evolution in industrial microorganisms.

J. Microbiol. Biotechnol. 2020; 30: 793-803

Tolerance improvement of Corynebacterium glutamicum on lignocellulose derived inhibitors by adaptive evolution.

Appl. Microbiol. Biotechnol. 2018; 102: 377-388

Stress-tolerant non-conventional microbes enable next-generation chemical biosynthesis.

Nat. Chem. Biol. 2020; 16: 113-121

Muconic acid production from glucose and xylose in Pseudomonas putida via evolution and metabolic engineering.

Nat. Commun. 2022; 13: 4925

Sea water as a reaction medium for bioethanol production.

in: Patra J. Microbial Biotechnology. Springer, 2018: 171-192

Halophiles and their vast potential in biofuel production.

Front. Microbiol. 2019; 10: 1895

Halophiles, coming stars for industrial biotechnology.

Biotechnol. Adv. 2015; 33: 1433-1442

The establishment of a marine focused biorefinery for bioethanol production using seawater and a novel marine yeast strain.

Sci. Rep. 2018; 8: 12127

Non-sterilized fermentation of 2,3-butanediol with seawater by metabolic engineered fast-growing Vibrio natriegens.

Front. Bioeng. Biotechnol. 2022; 10955097

Rational flux-tuning of Halomonas bluephagenesis for co-production of bioplastic PHB and ectoine.

Nat. Commun. 2020; 11: 3313

Stoichiometric and kinetic analysis of extreme halophilic Archaea on various substrates in a corrosion resistant bioreactor.

New Biotechnol. 2014; 31: 80-89

A beginner’s guide to bioprocess modes-batch, fed-batch, and continuous fermentation.

Application Notes-Eppendorf. 2019; 408: 1-16

A review of control strategies for manipulating the feed rate in fed-batch fermentation processes.

J. Biotechnol. 2017; 245: 34-46

Open and continuous fermentation: products, conditions and bioprocess economy.

Biotechnol. J. 2014; 9: 1503-1511

Development of a cell-recycled continuous fermentation process for enhanced production of succinic acid by high-yielding mutants of Actinobacillus succinogenes.

Biotechnol. Bioprocess Eng. 2021; 26: 125-136

Homo-succinic acid production by metabolically engineered Mannheimia succiniciproducens.

Metab. Eng. 2016; 38: 409-417

Improve gamma-aminobutyric acid production in Corynebacterium glutamicum by optimizing the metabolic flux.

Syst. Microbiol. Biomanuf. 2022; 2: 305-316

Designing an irreversible metabolic switch for scalable induction of microbial chemical production.

Nat. Commun. 2021; 12: 3419

Systematic engineering of TCA cycle for optimal production of a four-carbon platform chemical 4-hydroxybutyric acid in Escherichia coli.

Metab. Eng. 2016; 38: 264-273

Production of succinic acid by metabolically engineered microorganisms.

Curr. Opin. Biotechnol. 2016; 42: 54-66

Production of succinic acid by engineered E. coli strains using soybean carbohydrates as feedstock under aerobic fermentation conditions.

Bioresour. Technol. 2013; 130: 398-405

Metabolic engineering of Escherichia coli for the production of succinate from glycerol.

Metab. Eng. 2010; 12: 409-419

Metabolic impact of the level of aeration during cell growth on anaerobic succinate production by an engineered Escherichia coli strain.

Metab. Eng. 2010; 12: 499-509

Current advance in biological production of malic acid using wild type and metabolic engineered strains.

Bioresour. Technol. 2018; 258: 345-353

Combining rational metabolic engineering and flux optimization strategies for efficient production of fumaric acid.

Appl. Microbiol. Biotechnol. 2015; 99: 8455-8464

Oxidative stress-related responses of Bifidobacterium longum subsp. longum BBMN68 at the proteomic level after exposure to oxygen.

Microbiology. 2011; 157: 1573-1588

Microaerobic fermentation of Lactobacillus acidophilus within gut microbiome physiological conditions by BioFlo® bioprocess control stations.

Application Notes-Eppendorf. 2019; 412: 1-8

Automated measurement and monitoring of bioprocesses: key elements of the M3C strategy.

in: Mandenius C.F. Titchener-Hooker N. Measurement, Monitoring, Modelling and Control of Bioprocesses. Springer, 2012: 1-33

Succinic acid production from glycerol by Actinobacillus succinogenes using dimethylsulfoxide as electron acceptor.

New Biotechnol. 2014; 31: 133-139

Metabolic engineering of Escherichia coli for the enhanced production of l-tyrosine.

Biotechnol. Bioeng. 2018; 115: 2554-2564

Bioprocessing in the digital age: the role of process models.

Biotechnol. J. 2020; 15: 1900172

Nonlinear model predictive control of fed-batch fermentations using dynamic flux balance models.

J. Process Control. 2016; 42: 137-149

Real-time monitoring of bacterial growth kinetics in suspensions using laser speckle imaging.

Sci. Rep. 2020; 10: 408

On-line analysis and in situ pH monitoring of mixed acid fermentation by Escherichia coli using combined FTIR and Raman techniques.

Anal. Bioanal. Chem. 2020; 412: 7307-7319

Scale-up of industrial microbial processes.

FEMS Microbiol. Lett. 2018; 365: fny138

A model-based framework for parallel scale-down fed-batch cultivations in mini-bioreactors for accelerated phenotyping.

Biotechnol. Bioeng. 2019; 116: 2906-2918

Developing a computational framework to advance bioprocess scale-up.

Trends Biotechnol. 2020; 38: 846-856

Reproduction of large-scale bioreactor conditions on microfluidic chips.

Microorganisms. 2019; 7: 105

Development of dynamic compartment models for industrial aerobic fed-batch fermentation processes.

Chem. Eng. J. 2021; 420130402

Grand research challenges for sustainable industrial biotechnology.

Trends Biotechnol. 2019; 37: 1042-1050

Engineering thermophilic Geobacillus thermoglucosidasius for riboflavin production.

Microb. Biotechnol. 2021; 14: 363-373

Metabolic engineering of microbial competitive advantage for industrial fermentation processes.

Science. 2016; 353: 583-586

Synthesis and analysis of separation processes for extracellular chemicals generated from microbial conversions.

BMC Chem. Eng. 2019; 1: 21

Synthesis and analysis of separation networks for the recovery of intracellular chemicals generated from microbial-based conversions.

Biotechnol. Biofuels. 2017; 10: 119

Metabolic engineering of Escherichia coli for secretory production of free haem.

Nat. Catal. 2018; 1: 720-728

Microbial production of methyl anthranilate, a grape flavor compound.

Proc. Natl. Acad. Sci. U. S. A. 2019; 116: 10749-10756

Engineering of unconventional yeast Yarrowia lipolytica for efficient succinic acid production from glycerol at low pH.

Metab. Eng. 2017; 42: 126-133

Monascus ruber as cell factory for lactic acid production at low pH.

Metab. Eng. 2017; 42: 66-73

Machine learning applications in systems metabolic engineering.

Curr. Opin. Biotechnol. 2020; 64: 1-9

Optimizing chemical reactions with deep reinforcement learning.

ACS Cent. Sci. 2017; 3: 1337-1344

Systematic strategies for developing phage resistant Escherichia coli strains.

Nat. Commun. 2022; 13: 4491

Succinate production in dual-phase Escherichia coli fermentations depends on the time of transition from aerobic to anaerobic conditions.

J. Ind. Microbiol. Biotechnol. 2002; 28: 325-332

Genome-based metabolic engineering of Mannheimia succiniciproducens for succinic acid production.

Appl. Environ. Microbiol. 2006; 72: 1939-1948

Development of chemically defined medium for Mannheimia succiniciproducens based on its genome sequence.

Appl. Microbiol. Biotechnol. 2008; 79: 263-272

Highly selective production of succinic acid by metabolically engineered Mannheimia succiniciproducens and its efficient purification.

Biotechnol. Bioeng. 2016; 113: 2168-2177

Synthesis, characterization, and application of fully biobased and biodegradable nylon-4, 4 and-5, 4.

ACS Sustain. Chem. Eng. 2020; 8: 5604-5614

Challenges and opportunities in bringing nonbiological atoms to life with synthetic metabolism.

Trends Biotechnol. 2022; ()

Recombinant Escherichia coli as a biofactory for various single-and multi-element nanomaterials.

Proc. Natl. Acad. Sci. U. S. A. 2018; 115: 5944-5949

Biosynthesis of inorganic nanomaterials using microbial cells and bacteriophages.

Nat. Rev. Chem. 2020; 4: 638-656

- Coinsmart. Europe’s Best Bitcoin and Crypto Exchange.Click Here

- Platoblockchain. Web3 Metaverse Intelligence. Knowledge Amplified. Access Here.

- Source: https://www.cell.com/trends/biotechnology/fulltext/S0167-7799(22)00276-1?rss=yes