Cross-docking services can let you ship goods faster and reduce warehousing costs. This is because cross-docking involves delivering products from manufacturers directly to the destination with little to no storage time. Moreover, this service reduces the chances of product damage and loss of inventory, as it involves minimal handling of goods.

However, before deciding whether cross-docking is beneficial for your business, it is crucial to note both its pros and cons. This article will provide you with an objective look at the pros and cons of cross-docking.

But first, what exactly are cross-docking services?

What are Cross-Docking Services?

Cross-docking services involve the transfer of goods from an inbound carrier to an outbound carrier with minimal to no warehousing and material handling. Once these goods arrive at a cross-dock facility, they are quickly sorted and shipped directly to the destination. This results in reduced storage costs and shipping times, as well as improved customer satisfaction.

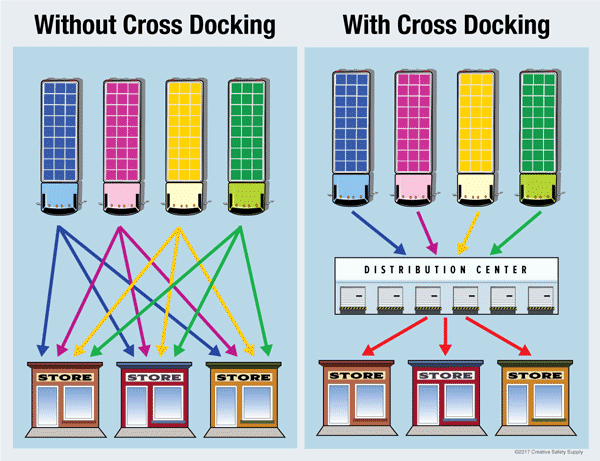

See the image below for a visual representation of cross-docking.

Cross-docking services can be used for a wide range of reasons, some of which are as follows:

-

Fluctuations in Demand – As the demand for some products changes over time, storing them for longer than required can potentially reduce their overall value. With cross-docking services, you can source and ship such items per demand and avoid long storing periods.

-

Shipping Time-Sensitive Items – Some goods need to be shipped as quickly as possible, as their quality might deteriorate if they are stored for an extended period. Cross-docking services let you avoid storing goods for a long time and ship them promptly.

-

Incoming Loads from Multiple Suppliers – Through a cross-dock facility, you can receive, sort, combine, and ship loads coming from multiple suppliers in an effective and timely manner.

-

Shipping Overweight Cargo – If your transport vehicles are overweight, cross-docking services can facilitate efficient unloading and shifting of goods to help you stay compliant with the guidelines.

Now, let’s learn about some pros and cons of cross-docking services.

Pros of Cross-Docking Services

1. High Product Turnover Rates

Utilizing cross-docking services can improve your product turnover rates, as the goods are moved quickly through a cross-dock terminal with minimal to no storage time. As a result, you can reduce your inventory shelf-time, which in turn can increase your business’s profitability.

2. Reduced Storage & Labor Costs

Storage-related expenses are reduced through cross-docking services, as the need to store products for extended periods is minimized. This reduction in expenses can then translate to cost savings for your business.

Moreover, since goods are no longer required to be picked and put away, this service minimizes material handling, resulting in reduced labor-related expenses.

3. Minimized Product-Related Risks

In cross-dock warehouses, various risks involved with the handling of goods are minimized. Since products are no longer shuffled in and out of storage areas, warehouse equipment and material handling are significantly reduced. As a result, product damage, loss of inventory, and potential human errors are avoided.

4. Increased Customer Satisfaction

As cross-dock service eliminates the need for storage of goods, they can be shipped to the customers in an efficient and expedited manner. This can positively impact your customer service as delivery lead-times are shortened and the products are delivered on-time.

Cons of Cross-Docking Services

1. Requires Sufficient Transport Carriers

A cross-dock facility relies heavily on its transport carriers since goods are shipped promptly and not put in storage. As a result, there is a need for a sufficient number of transportation carriers to ensure the smooth and efficient functioning of the cross-dock system.

2. Need for Reliable Suppliers

Reliable suppliers are essential to effectively facilitate cross-docking operations. This is because cross-docking requires accurate and on-time deliveries from suppliers to ensure goods can be shipped to customers in a timely manner.

3. Requires In-Depth Planning & Coordination

Cross-dock service requires in-depth planning and supplier coordination, as it involves various considerations, such as supply-demand analysis, shipment schedules, and more. Without proper planning and execution, there is a high probability the efficiency and reliability of the cross-dock system can be negatively impacted.

Summary

Cross-docking services can help you ship goods faster, reduce warehousing costs, and minimize product-related risks. However, it is essential to take into consideration the trade-offs associated with this service. If you can effectively manage its drawbacks, then cross-docking might be the solution to boost the profitability of your business.

To find solutions to reduce your shipping times, costs, and product-related damages, go to our Solutions Finder tool.

If you want to learn about warehouse technology and optimizing warehouse processes, you can follow us on LinkedIn, YouTube, Twitter, or Facebook. If you have other inquiries or suggestions, don’t hesitate to contact us here. We’ll be happy to hear from you.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- Platoblockchain. Web3 Metaverse Intelligence. Knowledge Amplified. Access Here.

- Source: https://articles.cyzerg.com/cross-docking-services-pros-and-cons