[embedded content]

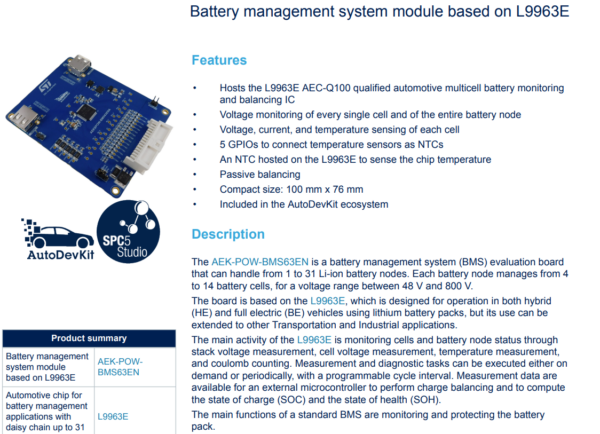

This week’s EYE ON NPI (video) is a part of a balanced breakfast, wait no we mean a balanced battery pack! It’s STMicroelectronics’ AEK-POW-BMS63EN Battery Management System Module featuring the L9963E automotive multicell battery monitoring and balancing IC.

This chip brings automotive-grade battery management to any product designer, at a great price, so you can keep your batteries monitored and balanced for a safe and long usage life.

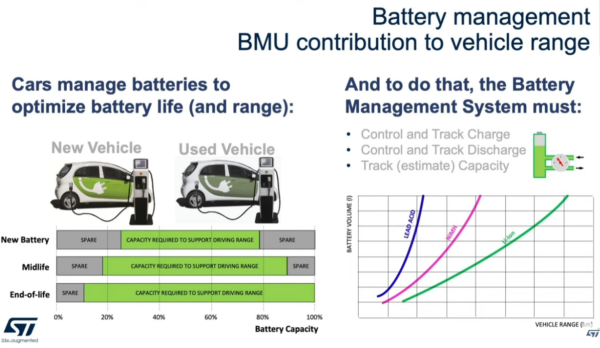

All cars have batteries, and if you have a internal combustion engine car, you’re probably familiar with the 12V lead acid battery that needs replacing every 5-10 years, these batteries do not power the moving car itself, just the lights, stereo, electrical system and the spark plugs needed to get the engine running.

These batteries are pretty simple, there are two big lugs, a ground and a +12V, inside is 6 series Lead Acid cells, of 2V nominal each. The battery is charged by the engine, and while you don’t want to over or under-charge lead-acid batteries are pretty forgiving.

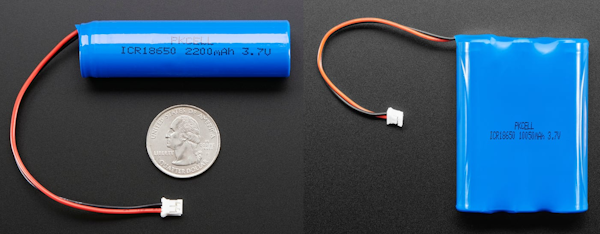

In EV electric vehicles, the batteries have to have much higher energy density so they use Lithium Ion cells, often ‘18650’ cylindrical cells. These are connected in long series strings, to provide high voltages and then parallelized to give high currents. The same batteries are also used in e-scooters, e-skateboards and other micro-mobility devices, they’re very low cost, and packs are easy to make.

BUT, Lithium-based batteries, as part of the high energy density, have a lower life and are more sensitive to charge and discharge cycles.

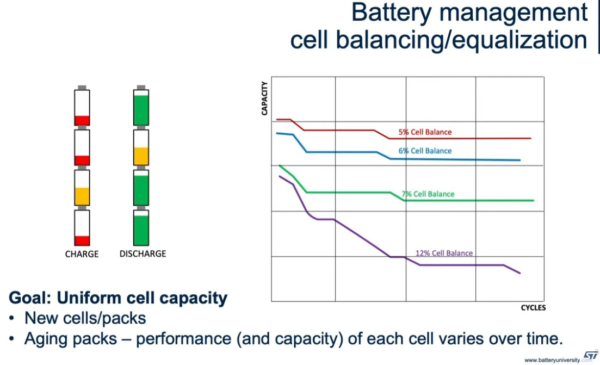

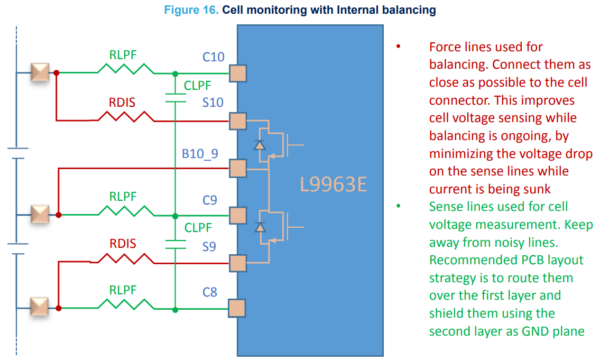

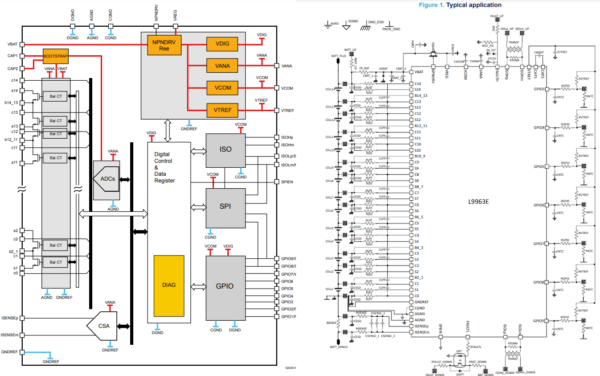

to worry One of the things we have about is keeping the batteries balanced. That means that we have to monitor each cell in the string carefully to make sure the state of charge matches the rest. The ST L9963E does this in two ways. First is per-cell voltage monitoring, and also per-string current monitoring.

to worry One of the things we have about is keeping the batteries balanced. That means that we have to monitor each cell in the string carefully to make sure the state of charge matches the rest. The ST L9963E does this in two ways. First is per-cell voltage monitoring, and also per-string current monitoring.

Once each cell’s state of charge is known, internal or external FETs can be used to shunt current from each cell during the charge cycle, with the goal of bringing the cells back into balance at the cost of charge rate because now we’re going to charge every cell as slow as the ‘worst’ cell. However, this keeps the system safe from overcharging, and is a lot less expensive/complex than active balancing.

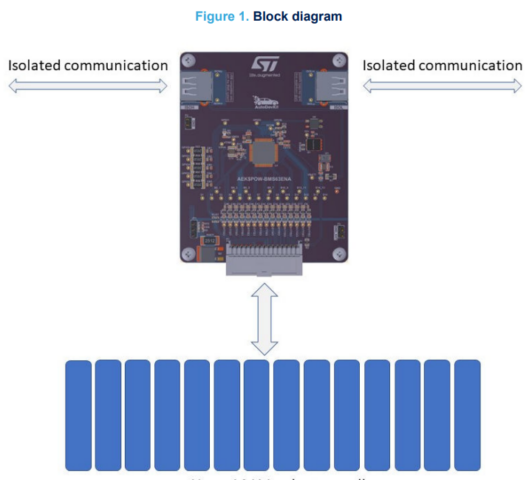

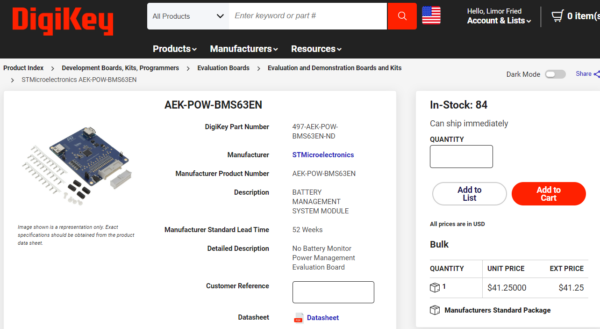

Since this chip is fairly complex, having a ready-to-go eval board that is already set up with the isolated SPI interface is a worthy investment. You can get started fast and just integrate the AEK-POW-BMS63EN directly into your prototype while you work out your battery management system.

The board has USB-like ports on either side but these are actually two-wire isolated SPI, which protects your low-voltage microcontroller or computer from possibly getting zapped by the 48V+ battery.

You can use USB A-A cables, since the pinout will work fine, but just be aware you can’t plug it into your computer. To connect the opposite side to your micro, you’ll also need to pick up a de-isolator AEK-COM-ISOSPI1.

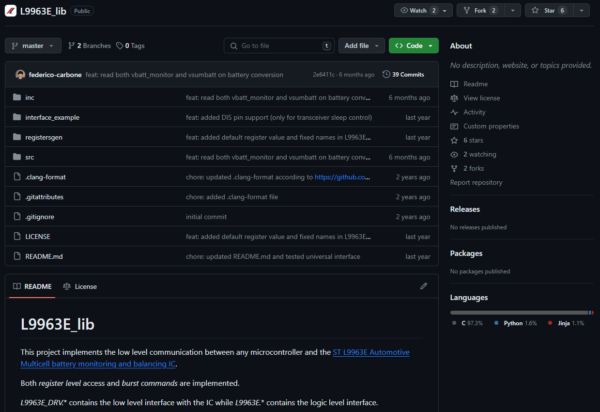

Finally you’ll need to write the SPI interface library for managing the battery. We found one published L9963E library that might get you started – written by the Squadra Corse student Formula SAE teams.

If you have a project with large batteries and you want an automotive-grade battery management system, the L9963E automotive multicell battery monitoring and balancing IC and matching Evaluation Board will make it easy to get started. And best of all, both are in stock right now for purchase at DigiKey! Place your order today and your order will ship in moments, so you can get started with battery management by tomorrow afternoon.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://blog.adafruit.com/2024/01/11/eye-on-npi-stmicroelectronics-aek-pow-bms63en-battery-management-system-module-eyeon-npi-digikey-adafruit-digikey-st_world-adafruit/