Large-area solar cells made from hybrid perovskite materials have taken a step closer to commercialization thanks to researchers in Australia and the UK who fabricated the cells with industrial methods for the first time. Produced under ambient conditions using a technique known as roll-to-roll printing, the cells show relatively high power conversion efficiencies of up to 15.5% for individual small-area cells and 11% for serially-connected ones in large-area modules. According to the researchers, the cells would also be cheap to produce, with calculated costs dropping to $0.70 per watt once production hits 1 000 000 m2 per year.

A perovskite material is termed “hybrid” when it contains both inorganic and organic components. Like all perovskites, hybrids have the chemical formula ABX3, but in this case A is an organic cation, while B is lead and X can be iodide, bromide or another halide. Structurally, they contain a lead halide framework that is filled with small organic cations, and they show much promise for thin-film solar cells because their tuneable bandgaps allow them to absorb light over a broad range of solar-spectrum wavelengths.

“We have been working on printed organic solar cells for a long time, but the field of organic solar cells was advancing relatively slowly when perovskite solar cells emerged,” says Doojin Vak of Australia’s Commonwealth Scientific and Industrial Research Organisation (CSIRO), who led the project together with colleagues from the University of Cambridge, Monash University and the University of New South Wales.

For researchers like Vak, the exciting thing about hybrid perovskite solar cells is that their power conversion efficiencies are, in principle, on par with those of established solar-cell materials such as silicon, gallium arsenide or cadmium telluride. In practice, however, high-efficiency hybrid perovskite solar cells have so far only been demonstrated in the laboratory. Making efficient large-area devices from these materials using industrial processes remains challenging.

An 11% efficiency on 50 cm² panels

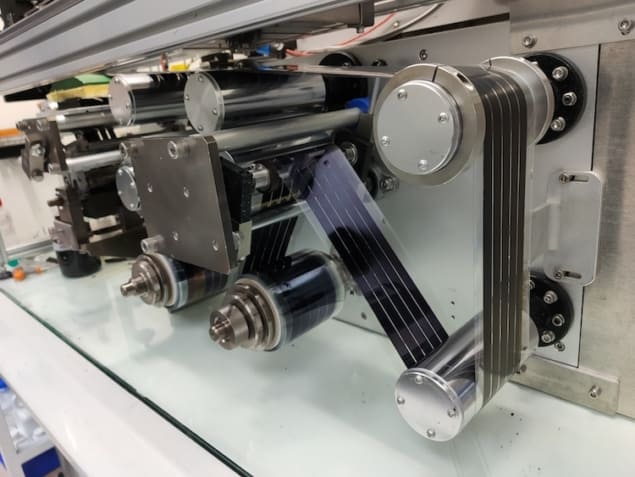

In the latest work, Vak and colleagues showed that they could produce hybrid perovskite solar panels with efficiencies of 11% and an area of up to 50 cm2 using roll-to-roll printing. This technique produces cells in a continuous process that resembles the way newspapers are printed, with successive coating, printing and drying stages transforming a roll of film at one end to a roll full of the finished product at the other.

Many industrial processes complete all these fabrication steps in a single pass. In this case, however, the researchers used multiple runs to fabricate their devices. They also replaced the vacuum-based metal electrodes conventionally employed in roll-to-roll printing with printed carbon electrodes that are compatible with perovskite materials.

Thanks to this adjustment, the team was able to fabricate and analyse more than 10 000 solar cells per day. This “high throughput” experiment allowed the researchers to rapidly identify optimal values for various processing parameters, which increased the efficiency of the final devices.

Prototypes for various applications

“We thought that perovskite solar cells could also be fully printed like organic-based ones and we have made good progress,” Vak says. “The last hurdle was eliminating vacuum-based back electrodes and we managed to achieve that goal in this work.”

Plasma, nanoparticles and printed electronics

The researchers say the modules they produced could be used as prototypes for testing in various applications.“While it is not at the level to be readily adopted in traditional fields where you would normally use mature solar technologies like silicon solar cells, we have identified applications and premium markets in which this technology will have a competitive advantage,” Vak says. “For example, we have been looking into space applications and have installed printed perovskite solar modules on a recently launched satellite.”

In this study, which is published in Nature Communications, the biggest solar modules the researchers fabricated measured 10 cm x 10 cm. While this is considered sizeable within academic research, it is still too small for real-world applications. The next step for the researchers is therefore to scale up their technique. “Fortunately, we have just completed the installation of a state-of-the-art printing facility for perovskite solar cells at CSIRO and we will be able to progress the technology with this new pilot-scale printer,” Vak tells Physics World.

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://physicsworld.com/a/roll-to-roll-fabricated-hybrid-perovskite-solar-cells-reach-record-efficiencies/