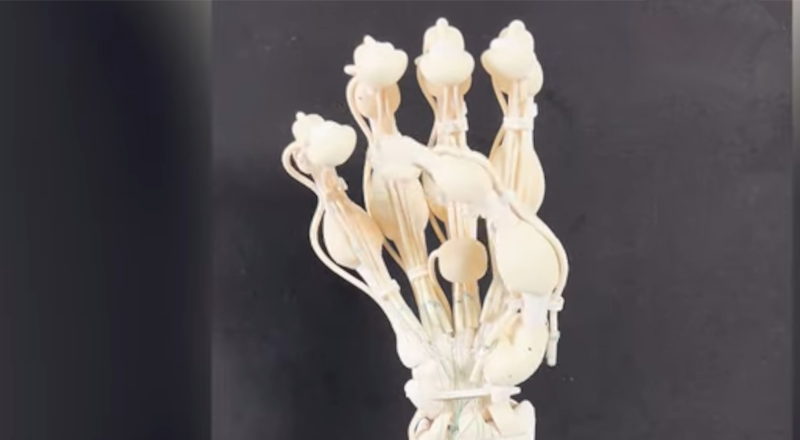

What do you get when you mix rigid and elastic polymers with a laser-scanning 3D printing technique? If you are researchers at ETH Zurich, you get robot hands with bones, ligaments, and tendons. In conjunction with a startup company, the process uses both fast-curing and slow-curing plastics, allowing parts with different structural properties to print. Of course, you could always assemble things from multiple kinds of plastics, but this new technique — vision-controlled jetting — allows the hands to print as one part. You can read the full paper from Nature or see the video below.

Wax with a low melting point encases the entire structure, acting as a support. The researchers remove the wax after the plastics cure.

The technique isn’t just for hands. The paper shows a functional heart pump, for example. The printer uses an inkjet arrangement to deposit material and a UV LED curing system. A laser scanner generates a high-resolution map of the build surface, allowing the controller to adapt the print layers.

This might not be a technique for every day although, honestly, we want to hear more about the wax support systems. However, for the right print job, the ability to mix differing kinds of polymer may allow for unique and cost-effective designs.

We’d like to see how this hand compares to the Clone Hand. Don’t want to 3D print? Stop by the hardware store.

[embedded content]

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://hackaday.com/2023/11/16/robot-hand-has-good-bones/