| Nov 24, 2023 |

|

|

|

(Nanowerk News) Microrobotics has advanced rapidly in recent years, allowing scientists to build minuscular machines able to penetrate hard-to-reach environments from inside the human body to contaminated waste sites. Propelling these tiny robots requires clever solutions, as their tiny size means they operate in a realm dominated by viscosity rather than inertia. One popular approach uses repeated compression and rarefaction of air bubbles induced by acoustic waves to produce microstreaming flows that can drive robotic motion. However, the fragility of individual bubbles and limited force output has constrained widespread adoption.

|

|

Researchers have long looked to biology for robotic inspiration. Now a team from the University of Twente led by Sarthak Misra takes cues from the world of acoustic metamaterials to create a powerful new acoustically-powered microrobot design. Their bioinspired approach could open new possibilities for deploying microbots in biological sampling, clinical medicine, environmental remediation and more.

|

|

The team reported their findings in Advanced Intelligent Systems (“Acoustically Actuated Flow in Microrobots Powered by Axisymmetric Resonant Bubbles”).

|

|

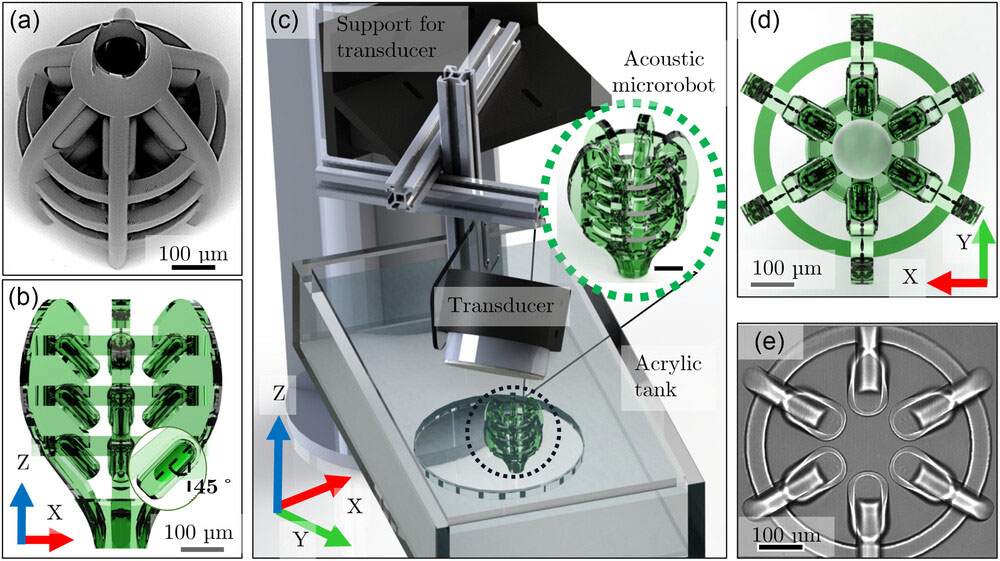

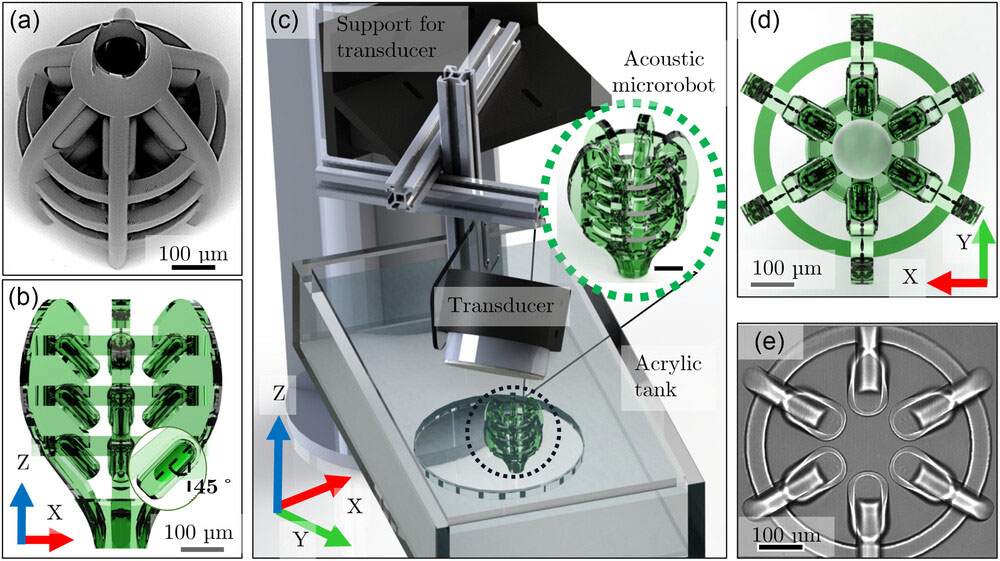

| a) Micrograph of proposed acoustic metamaterial-inspired microrobot depicting the arrangement of cavities, with b) side view of the microrobot with the constituent cavities that entrap gas bubbles (inset). c) Schematic depicting the microrobot immersed in the acoustic characterization setup that comprises a large acrylic tank (300mm x 200mm x 100 mm) with a designated circular workspace and immersible ultrasound transducer (center frequency 110 kHz, cross-sectional diameter 60 mm, PA1954, Precision Acoustics, UK). Scale bar is 100 μm. Top view of the microrobot: d) schematic showing the rings connecting the cavities; e) Nanoscribe view of the microrobot during its fabrication. (Reprinted with permission from Wiley-VCH Verlag)

|

Bubbles as Metamaterial Building Blocks

|

|

Metamaterials manipulate sound waves or light in unconventional ways by repeating structural elements, known as unit cells, in periodic patterns. This periodically repeating internal architecture interacts with impinging waves to produce astonishing properties like a negative refractive index. By distributing many bubbles in an organized array, scientists realized they could create acoustic metamaterials with uniquely tailored acoustic characteristics.

|

|

Research into such “bubble metamaterials” accelerated following their demonstration for exotic applications like submarine sound masking. However, almost all designs to date use relatively large bubbles, over 300 µm across. Scientists have struggled producing functioning acoustic metamaterials with microbubbles below 100 µm despite their potential utility.

|

|

The UTwente team wondered if they could harness microbubble acoustic metamaterials principles not just for acoustic cloaking but also to improve microscale robot design. Their new microrobot distributes 18 resonant microbubbles 100 µm in length, acting as metamaterial unit cells, in a 3D axisymmetric pattern. Despite the engineering challenge of microfabricating such a structure, this architecture offers significant advantages.

|

More Bubbles, More Flow

|

|

In microbots, bubbles serve dual purposes as on-board motors and propulsive thrusters. Individual microbubbles oscillate powerfully when stimulated by incoming acoustic waves at their resonant frequency, creating strong local flow known as microstreaming. However, below around 300 µm diameter viscosity severely constrains bubble oscillation. This limits the motive force available, requiring high intensity acoustic stimulation that risks detrimental bioeffects.

|

|

Fortunately, what microbubbles lack in individual force generation they make up for in teamwork. The Twente group realized that an organized collective layout boosts net fluid flow beyond the sum of the constituent bubbles’ contributions. By coherently superimposing the oscillations from multiple microbubbles, they create significantly enhanced microstreaming effects capable of powering robotic propulsion and manipulation.

|

|

Where previous microbot designs positioned just a few bubbles in smooth linear or radial patterns, the team’s metamaterials-inspired 3D axisymmetric architecture containing 18 bubbles in periodic symmetry enables stronger streaming flows along a central axis using lower intensity ultrasound. Particle tracing experiments revealed a nearly 80% increase in the peak microstreaming velocity compared to their previous 6-bubble microrobot under the same acoustic conditions. This suggests the collective bubble layout better harnesses the available acoustic energy.

|

Re-Engineering Microrobots as Macroscopic Systems

|

|

Rather than miniaturizing further as is the prevailing trend in microrobotics, the researchers chose to scale their design up. Fabricating the bot using high resolution direct laser writing 3D printing allows incorporating subtle structural features like re-entrant nooks that passively stabilize the bubbles without special surface chemistry processing. Crucially, enlarging the overall structure to a 0.5 mm scale makes it far simpler to handle and deploy than typical micron-scale designs.

|

|

Counterintuitively, going bigger opens new possibilities. Despite having 18 microbubbles each 100 µm long as its functional components, the millimeter-scale platform behaves essentially like a macroscale robotic system. Yet it retains all the performance advantages inherent to microbubbles compared to larger bubbles, especially the ability to oscillate at high frequencies in response to high frequency ultrasound. This best-of-both-worlds hybrid strategy could become a new paradigm in microrobotics engineering.

|

Putting Highly Agile Microbots to Work

|

|

To demonstrate the capabilities of their acoustically powered millibot, the researchers showed how it can use streaming-induced suction to pull in and remove debris. This levitation and clearing functionality could be valuable for biological sampling or waste removal tasks in confined or hard-to-reach spaces.

|

|

When actuated at specific ultrasound frequencies around 65-70 kHz, the periodic microstreaming flows generate enough force for the microrobot to orient itself vertically and hover steadily. Switching frequencies modulates its motion, allowing transport across distances over 10 times the bot diameter. Harnessing these strong but precisely controllable streaming flows, the bot can attract nearby microparticles and living cells, filtering them into its internal channel. It then ejects the collected debris away from the surface.

|

|

With further development, such acoustically-powered millibots could offer contactless extraction and filtration functionality beyond current microscale sieving devices. Their hovering ability enables access through elaborate 3D terrains. This could be invaluable for sampling tissue or biofluids in crevices inside the human body for biopsies or lab-on-a-chip analysis. It also suits them for circulation inside complex microfluidic devices to dynamically direct and manipulate flows and particles.

|

|

Outside biological contexts, teams of the bots deployed en masse may prove useful for environmental remediation efforts, able to percolate through contaminated pore spaces in soils to adsorb chemical pollutants or transport enzyme-infused beads to catalyze waste degradation. Their versatility coupled with simple acoustic power and control makes them well suited for operation in remote or hazardous environments where direct human intervention is unfeasible.

|

Broader Impacts

|

|

By creating microbots with new capabilities, while simultaneously easing production and handling, the Twente team’s research showcases the merits of applying acoustic metamaterials principles in unconventional ways. Their creative repurposing of the orderly bubble arrangement paradigm introduces fresh ideas to microrobotics and microfluidics. It substantiates that hybridizing microscale components with larger platforms can markedly improve system performance. This upends the common assumption that miniaturization is inherently superior.

|

|

Moreover, their adoption of simplified fabrication schema not requiring extensive chemical surface modification or nanoscale moving parts makes adopting the new technology far more accessible. By showing microscale functionality need not equate to microscale constructs, they pave the way for engineers with common rapid prototyping tools like 3D printers to participate in creating the next generation of acoustically-powered microrobots.

|

|

The bots’ demonstrated utility for biological sampling and debris clearance presages potential applications in lab-on-a-chip devices for point-of-care diagnostics, toxin scavenging, and microfluidic quality control suited even for resource limited contexts and developing economies. Although significant development remains before such microbots reach clinic or field, the study constitutes an important early step toward enabling real-world microrobotic solutions for medicine, environmental protection and beyond.

|

- SEO Powered Content & PR Distribution. Get Amplified Today.

- PlatoData.Network Vertical Generative Ai. Empower Yourself. Access Here.

- PlatoAiStream. Web3 Intelligence. Knowledge Amplified. Access Here.

- PlatoESG. Carbon, CleanTech, Energy, Environment, Solar, Waste Management. Access Here.

- PlatoHealth. Biotech and Clinical Trials Intelligence. Access Here.

- Source: https://www.nanowerk.com/news2/robotics/newsid=64110.php