Taunton, United States. 17 August, 2022 – Harpak-Ulma, the industry provider in smart, connected packaging solutions, has been selected by a major medical device producer to provide automated flow wrap packaging lines for pipette tip production. The move will ensure reliable, US-based production of a vital tool utilised to dispense precise amounts of liquid in disease research and diagnostic labs.

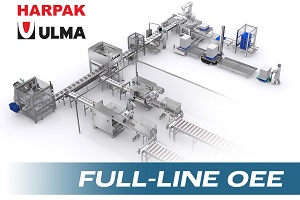

Harpak-ULMA will deploy smart, connected packaging platforms outfitted with highly automated product loading and secondary/tertiary pack-out operations in the partnership project. The company’s solutions will meet or exceed the high levels of scalability, medical device packaging quality, and overall throughput demanded at extreme production levels. A key selection criterion was Harpak-ULMA’s ability to deliver an end-to-end, integrated solution, from upstream product handling and product tracking through primary and secondary packaging to integrated pack-out stations. This total line solution enables tracking of Line OEE in addition to individual equipment OEE, enabling a centralised control system to optimise the communications between equipment.

The key to sustaining high-volume, mission-critical packaging output is a focused approach to OEE (overall equipment effectiveness) optimisation, including minimising all variations of line downtime. Moreover, the digital transformation of packaging operations can dramatically improve line uptime. “Our smart, connected packaging platforms enable innovative technologies to achieve these outcomes – all while maximising line output, scalability, and flexibility,” states Nick Kirichkow, Harpak-ULMA medical industry product manager.

Harpak-ULMA’s multi-year, multi-phase strategic plan addresses advanced machine self-diagnosis, remote OEE monitoring, and analytics deployment, augmented reality (AR) experiences for training, work instructions and maintenance routines, and real-time digital twins. The approach enables real-time performance monitoring, troubleshooting, and predictive maintenance solutions. Proactively identifying OEE variations and associated root causes uplifts overall line performance and throughput. Introducing front-line worker tools such as augmented reality (AR) experiences can accurately guide staff through complex repairs that may previously have required OEM field support – reducing overall mean-time-to-repair (MTTR). Smart, connected platforms also enable predictive maintenance capabilities – introducing the potential to all but eliminate unplanned line downtime.

Harpak-ULMA’s digital transformation strategy focuses on developing and deploying information-centric, next-generation packaging solutions, providing an additional strategic rationale for this high-profile government initiative. In addition, Harpak-ULMA’s end-to-end proven automation experience and capabilities offer a single point of accountability that helps to ensure on-time, on-budget solution commissioning.

“We are extremely proud to have been selected for such an important program. If the past few years have taught us anything, it’s that bringing technology and automation to bear in packaging operations, or any aspect of production, can be the difference between hitting the pause button on production – or not – during a public health emergency,” Roach adds. “The combination of smart, connected machines and automation helps ensure supply chain availability for products that are key to public health and safety. If there was any remaining doubt about that value proposition in the minds of manufacturing executives, the recent pandemic put that to bed.”

Comment on this article below or via Twitter: @IoTNow_OR @jcIoTnow.